Today’s B2B buyers are in control. They know what they want, and they know where to get it from. What they are concerned about is the “how”. This is a difficult challenge for fluid handling manufacturing businesses, which are already struggling with increased competition from global sourcing activities, and reverse engineered products from low-cost countries.

Watch the webinar recording of "The Future of Sales for Fluid Handling Manufacturers" here

What are your current challenges in manufacturing sales?

During our webinar, we asked our audiences what their challenges were. The chart shows the results of the poll, which comprises the top challenges that fluid handling manufacturers face today.

Results of the poll show the top fluid handling industry challenges that manufacturers face

All of the attendees were from the fluid handling industry. And it seemed that their top concern was ensuring healthy margins. Next on the list of challenges were navigating increased competition, and reducing the cost of sales. These are some of the key challenges that digital sales can address. Read on to find out more.

Customer centricity is critical for fluid handling manufacturers

At In Mind Cloud, our finger is always on the pulse of the industry. And here’s what we know. Your customers are as discerning as ever, but their demands have changed.

- Customers want flexibility. They want more options to buy your products, so they can buy on their terms. Evidence of this can be seen in the growth of rental markets—fueled by an increasing number of customers who prioritize speed over all else.

- Customers want to buy easily. They want OEMs who are easier to conduct business with. Sales teams that are working in siloes are becoming a barrier for your customers, and they are responding by gravitating towards OEMs that offer a seamless way to buy.

- Customers want self-service. They want a way to buy what they need when they need it. For customers, downtime can lead to lost production time that affects revenue. Their goal would be to minimize waiting time any way they can—including waiting for quotes or invoices.

Customers know what is possible and are constantly raising their expectations

Ease of doing business. The new frontier for fluid handling manufacturers

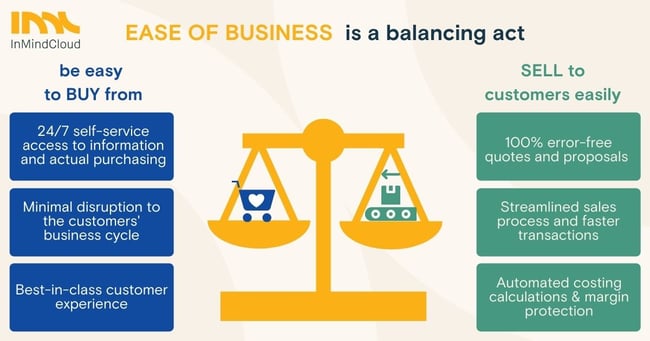

Customers are always looking for OEMs that are easier to buy from. But being easy to buy from doesn’t just mean having an online portal for self-serve checkout. Being easy to buy from spans the entire relationship with your customer—and starts from understanding their business challenges, through to serving their aftermarket needs.

Customers are not willing to deal with manufacturers who still have sales teams working in siloes. This prevents them from having a relationship with the rest of your business. When they have no visibility into your business—catalog, inventory, logistics, etc.—they won’t be able to strategize as effectively on their own business.

Manufacturers need to find the balance between the buying journey and buying process

From our perspective, we still see fluid handling manufacturers using traditional, analog methods to manage a highly complex sales process. There are also manufacturers who have decided to transform their sales using generic platforms that can’t deal with the complexity of manufacturing sales without expensive, time-consuming tweaks.

This can cause problems like:

- Delayed requests for quotes

- Misconfigured products

- Incorrect or superseded parts

Small problems can snowball into bigger problems

The problems which we described may seem small, but these problems can turn into massive issues for your business. One example that our fluid handling customers and their customers are familiar with is this. Superseded spare parts, and updated BOMs versus serial numbers of legacy asset sales. The pumps your business sells may have been the same model sold since the 1940s.

But over the years, advanced R&D on the product model could have led to incremental, or dramatic dimensional changes of rotor shafts, mechanical seal housings, and static rubber seals. It not only changes the part numbers but the new parts may have been modified to require additional parts to fit.

For customers, replacing a single part like a mechanical seal could mean replacing several other parts like the shaft—which could have been updated to only accommodate the new superseded mechanical seal. Without an up-to-date BOM, sales engineers or end-users—especially in remote regions—would not be able to order correctly and repair their critical assets on time.

And that costs your customers money. Your municipal, industrial, or mining customers could potentially incur millions of dollars in lost production or revenue when breakdowns and downtime occur.

Let sales work ON the business. Not IN the business.

Over the years, sales tools have evolved from fax and paper-filled offices to excel and emails. But the digitalization of sales is far from over. The next big point of relevance for OEMs is the transition from siloed tools, to a centralized data repository—a "digital brain trust" filled with:

- Engineering drawings

- Bill of Materials (BOMs)

- Marketing materials like whitepapers

- Industrial machinery & component documents

- New opportunity files

- Historic records of legacy sales notes

- Application points of interests

Making your sales data readily available is the next big point for reference

There is much more to what sales digitalization can do. But what we’ve just described above could already prove to be invaluable to fluid handling manufacturers that value the customer experience, and want to reduce costs by eliminating errors that cause rework in quotations, or even in shipping.

The methods may change, but the goal remains the same. Manufacturers want to let sales do what they do best—pursue opportunities that improve the business. With a digital sales platform, manufacturers can help free sales from tedious, time-consuming analog tasks by making the entire sales process more automated.

Getting “the right pump for the right job”

This is an old saying in the pump manufacturing industry because product application is critical to performance outcomes and life-cycle costs. Having the wrong product for the job could lead to wasted time, effort and money. Once you have the right outcomes at the right costs, your customers will return.

The same could also be said for sales digitalization software. Manufacturers need to find the right software that fits their business. In this context, the software that your business buys should be purpose-built for fluid handling manufacturing businesses. It should also be highly scalable, and easily adaptable to your sales process.

However, to get the “digital brain trust” we mentioned before, your digital sales software also needs to be integrated with your ERP. This step is critical for automation as digital sales software takes real-time sales relevant data OUT of its siloes, and makes it readily available for sales, partners, and customers.

Here’s a quick video that shows you just how it can make buying your complex fluid handling products and solutions a process that just takes minutes.

This is an example of what your sales process could be like in three months

Aftersales: A right job for digital sales

In our years of working with leading fluid handling manufacturers, we discovered that aftersales can benefit greatly from digital sales and automation. In the video above, we showed you how easy it can be for your customers to buy from your business. And this is a feature we know your customers will love.

Your end-users, key accounts’ purchasing departments, partners, and distributors prefer more autonomy. They want to do their jobs with minimal friction—like constantly asking for updated catalogs, back-and-forth with sales, searching for product serial numbers, matching with install-base, etc...

They want the power to initiate, execute, and complete transactions without talking to, or waiting for your sales team. With a digital sales platform, you can empower them with what they want, and more.

In a digital sales platform, your business not only provides them a way to buy online. The front-facing process is also supported by powerful backend processes that are tightly integrated with your ERP to empower customers with:

- Instant serial number searches

These features let your customers order the parts they need with confidence. Besides the ordering speed and pricing accuracy, BOM matching also ensures that they buy only the parts that fit the assets they own. Your customers (and business) don’t have to deal with misconfigurations or ordering of the wrong parts—which are a waste of time and money for both sides.

The right fit for any IT environment

Digital transformation for fluid handling manufacturers is a matter of “when.” But it also leads to one of the biggest concerns our customers have, which is their legacy software. In their ongoing digital transformation journey, they may have adopted single-purpose software to fill in gaps in their sales process.

Take spreadsheets for example. It is widely used by fluid handling manufacturers to keep track of operations. It is tremendously good at what it does, but without integration, data entry is a tedious, time-consuming process. However, phasing out spreadsheets is not feasible for many businesses, as it holds critical data that keeps the business running.

A modern digital sales platform is designed with this scenario in mind. It is built to be adaptable enough to fit and enhance the existing systems and tools your business uses. Spreadsheets can be uploaded to populate the system with costs, prices, and complex configuration models, eliminating the need for manual data transfer.

The goal? To remove the pain of modernizing your sales process.

Collaboration towards the right outcomes

Another cause of friction for fluid handling manufacturers is the traditional approval process. From our experience, the sales process works best when it performs like a pump that is well-lubricated with R&O oils. In this case, collaboration is the lubricant that keeps sales flowing. Sales teams need to collaborate with each other, the customer, and management, which makes the entire sales process very complex.

Any miscommunication can result in errors that lead to delays that can be costly for both the manufacturer and their customers. To facilitate sales, a digital sales platform intelligently orchestrates all collaboration activities and workflows to deliver:

- Structured tasks and meetings

- 360-degree account views for transparency across all teams

- Virtual teams that bring all stakeholders together with reminders and notifications

- Automated approvals that streamline the sales process

The final outcome? Your business gets a sales process that is optimized end-to-end. But more importantly, your business becomes more customer-centric and is always ready to deliver the best possible customer experience.

To get a deeper look at how you can successfully digitalize your sales process, download our latest ebook "Industry Spotlight: Digital Sales for the Fluid Handling Industry" here. In case you missed our webinar, you can watch it on-demand here:

Deutsch

Deutsch