Today, manufacturers recognize a CPQ’s importance in their business. It can single-handedly transform the way you sell your complex solutions and products. With a few clicks, it can generate an accurate, deal-winning quote on the same day—far faster than your competitors. It can eliminate disastrous errors that can unnecessarily cost you the deals your business needs. It can automatically calculate margins based on the latest prices, so you never send an unprofitable quote again.

If that sounded like a sales tool you needed yesterday, you are right. But hold on. We’ve just described the sales tool used by leading manufacturers years ago. They are now using a CPQ that is much more powerful and far more advanced. The modern CPQ considers the complexity—the growing number of products and combinations—of their business. It does this incredible feat through deep integration with their ERP, which allows it to access all engineering and product knowledge.

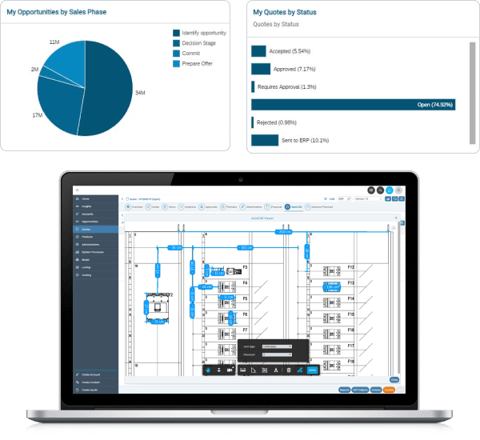

It then makes this knowledge accessible by advanced features like visual configuration support (using 2D drawings or 3D models) and all the digital tools in your business. This extends the classic CPQ function to serve not only sales but also your customers and your entire sales network via the cloud. Having a cloud-based CPQ has several advantages, and most of them are common across all cloud-based SaaS products. It keeps your costs low and can deliver results fast.

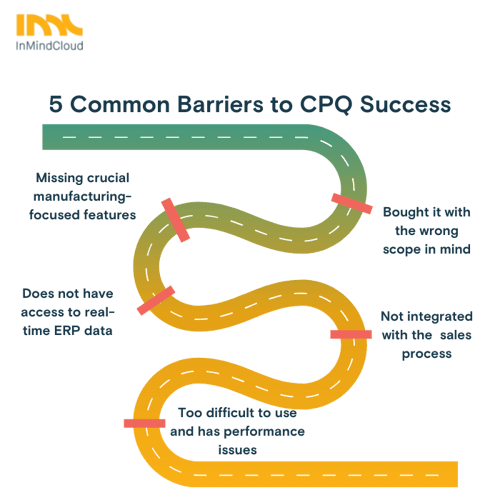

5 reasons why B2B manufacturing businesses are still not seeing success with CPQ

So why are manufacturers still failing at implementing a CPQ? This is a question that many manufacturers are struggling to answer. Onboarding a CPQ is supposed to be straightforward. You integrate it with your ERP and start using it. What can go wrong? As it turns out, plenty. Here are some of the top reasons why manufacturers do not see the value that a CPQ promises to bring to the business.

Download our Digital Sales Software Requirements Checklist to find out what features a winning CPQ software for manufacturing should have.

Manufacturers need to manage these common barriers to reach CPQ success

Your CPQ is missing crucial features your business needs

- Not all CPQs are built the same or offer the same features. This could lead to manufacturers onboarding software that is not a perfect match for their unique business requirements. It could be missing visual or CAD configuration, a feature that ensures non-technical users can still customize accurate quotes. It may not offer costing simulation, which helps protect margins. Or it could be missing a feature that lets you create order BOMs directly in your ERP. Going ahead with your software without critical features is a severe handicap that will hinder its ability to deliver the desired values.

Your CPQ purchase was made with the wrong scope

- Manufacturers often make the mistake of getting a CPQ for their present business, not their future business. This could result in a CPQ tuned for their current portfolio of products but not scalable enough to factor in new products. When that happens, a manufacturer’s growth, agility, and speed-to-market become severely limited. Adding new products, variants, or options could end up becoming a lengthy IT project. This can result in a manufacturer becoming slow in reacting to market demands or pushing out innovations, products, and services—and miss out on revenue that is on the table.

Your CPQ has no access to real-time ERP data

- ERP data maintenance is one of the first things we recommend all our customers do before implementing a digital solution that performs off that data. Bad data quality can cause errors to pile up, which in turn causes your CPQ to do more harm than good. It becomes an unreliable piece of software that your sales team avoids rather than uses to sell faster. On the other hand, not having real-time data access can cause your CPQ to underperform and introduce gaps that your sales team needs to fill in manually—bringing them back to where they were before a CPQ was introduced.

Your CPQ is not integrated with the end-to-end sales process

- A connected CPQ has the potential to transform your entire sales process. To do that requires seamless integration with your ERP and all your other digital tools. For example, CAD integration lets your CPQ auto-generate complex CAD documents to save time. Excel integration enables you to model product configurations easily by uploading an Excel document or downloading technical data in Excel format. CRM integration gives you a 360-degree overview of customer buying behavior that enables better upselling and cross-selling. ECommerce integration lets you offer self-service configuration and buying, and boost aftersales revenue. Without integration with all the tools and processes needed along the selling journey, your business can’t benefit from the enhanced accuracy and efficiency a CPQ has to offer.

Your CPQ is too difficult to use and struggles with performance issues

- A CPQ is powerful software. It can handle the complexity of your entire manufacturing business and make things easier for your sales team. But when the transition from spreadsheets to a modern CPQ is not implemented with your users in mind, it can overwhelm them. When your entire manufacturing business is made transparent with a CPQ, the sheer number of options, menus, buttons, and fields can be confusing. Without help from smart guidance, intelligent selling, built-in collaboration features, and a customizable, user-friendly interface, your users might not even know how to use it. When your CPQ is not helping your users perform their daily tasks well, the long-term adoption of the software is affected.

These are just some of the common pitfalls of implementing a modern CPQ in manufacturing. Some manufacturers could face even more unique challenges along the way. Leading manufacturers even take it one step further with their sales digitalization initiatives. They start with a customer-centric perspective and take a balanced approach to transform their sales process with a CPQ.

Leading manufacturers think about what their customers want.

A manufacturer’s customer just wants to get on with their business. They just want to buy a tractor, a lens polishing machine, or a filtration system and carry on pursuing what matters to them—growth. The challenge is, sometimes what they want to buy is much more than a bag of screws. They want a complex product with a thousand screws in a thousand different places. And they want to tell you where each screw goes, buy it easily, and have it delivered just as they ordered. Any manufacturer that can meet this demand effectively binds this customer to their business. It’s a win-win situation for both the client and the manufacturer. With this approach, a manufacturer has a clearly defined direction with their CPQ initiative—to make it easier for the customer to buy what they need.

So what does CPQ success look like?

Success in any digital transformation is complicated. Transformation success is made up of multiple wins on several fronts. In manufacturing sales, wins can be:

- Greater customer satisfaction and retention

- Faster innovation-to-market

- Greater sales efficiency and productivity

- Agility to react to changes in market demand

- Or all of the above if you digitalize the entire sales process.

In sales digitalization, CPQ is the engine that drives these changes. Here’s what you can expect when you get CPQ right.

Offer the convenience of a virtual showroom

There are plenty of reasons why your customers cannot visit your physical showroom. But there’s no reason why they can’t visit your virtual showroom. A connected CPQ integrated with your ERP enables your business to create an online showroom with real-time data. Prices, catalogs, promotions, innovations, inventory levels, options, variants—can all instantly be available with a few clicks. Sales, partners, and customers alike can easily configure what they want to buy online. With 2D or 3D visualization, they can even see what the final product can look like before they even pay.

Customers, partners, dealers can find everything they need in your virtual showroom

Blue forklift with a 6-cylinder diesel engine that can handle up to 6-ton loads? Simply choose the model, customize it to specifications, choose how many to buy, and hit the buy button (or generate an invoice and wait for a salesperson to assist in the transaction). If the customer isn’t sure about what other options are possible, smart selling capabilities in the system can even recommend options associated with the model—like introducing a similar forklift that is fully electric, just as powerful, but also eco-friendly.

Automated accuracy that ensures profitability

It is easy to price a bag of 1000 screws. But it’s a different level of complexity when it’s 1000 screws in 1000 different places. Pricing depends on materials used, what the screws are used for, and how difficult it is to get them in. Throw in an engine, seat, forks, overhead guards, counterweight, wheels, and other forklift parts, and pricing becomes exponentially more difficult. Add variants, options, and the pricing complexity goes up another notch. Manufacturers use spreadsheets to manage this complexity, but it’s no longer enough. Much of the pricing process can now be automated using real-time ERP data.

A Digital Sales Platform can ensure 100% accuracy to protect your margins

Automated rules and calculations use the latest prices, exchange rates to ensure 100% pricing accuracy across all regions. Automated constraints are also put in place to ensure that the sales team always offers discounts that do not cross the healthy-margin threshold. Together with dynamic cost estimations, customer-specific pricing, long-term cost tracking, and smart simulations, your manufacturing business can easily ensure profitability while keeping customers happy.

Streamline the sales workflow to reach customers first

The biggest advantage of a CPQ is speed. Manufacturers can use it to design solutions and generate a quote in minutes. However, quote approval is a process that manufacturers can overlook. A quote needs to pass through several layers and departments to ensure accuracy. This collaborative process alone can take days and become a bottleneck for your business, negating the benefits of producing a quote in minutes. Quotation accuracy is critical for both sides winning in a deal. But speed will decide if your business gets there before your closest competitors.

Sales automation helps push workflows and approvals along with minimal time wasted

That means your sales process needs to be seamless, cost-effective, and efficient. An advanced CPQ considers this and comes with intelligent automation that automates workflows and approvals so that your deals move along smoothly. It improves inter-department collaboration so that even decision-makers outside of sales are just as involved in the entire process. The result? Your business can generate a quote in minutes, get it approved in the next hour, and sales can send it out on the same day.

Digital success in a single Digital Sales platform

CPQ may be the engine of change in manufacturing sales. But that’s only if it powers your entire sales process. If your business buys a CPQ, you get a CPQ. If your business buys a Digital Sales Platform, you get a complete transformation of your manufacturing go-to-market. Integrate it with a CRM, you bring the power of a CPQ to the table in every engagement with your customers. Integrate it with eCommerce, your customers, partners, dealers, distributors have 24/7 controlled access to every product, service, and solution you sell. Integrate it with CRM and eCommerce?

Find out why manufacturers still fail to leverage their CRM

Find out why manufacturers still fail to get results from eCommerce

That’s end-to-end sales efficiency in a single, easy-to-maintain, and cost-effective platform. With it, your business can successfully digitalize the entire sales process with just one initiative. It delivers sales efficiency and accuracy, which leads to reduced costs. Lower costs lead to a competitive advantage that helps your business increase revenue. The benefits are inter-connected, and your business becomes much more competitive when serving the market.

This inter-connectivity of benefits is a distinct advantage of a Digital Sales Platform. If you have any questions, book a no-obligation consultation with our manufacturing sales experts to understand how our Digital Sales Platform is built to elevate manufacturing sales.

If you would like to take the next step towards sales digitalization, you can also give our interactive Digital Sales Software Comparision Checklist a try. All you need to do is answer a few short questions on your sales digitization goals, and it will generate a custom comparison checklist that helps you find the ideal digital sales software for your business.

You can use the Digital Sales Software Comparison Checklist to get an in-depth look at what your business needs to accelerate sales or turn it into a compliance table to find the best-fit software digitalization partner.

Deutsch

Deutsch