What to expect from this guide

In Mind Cloud has collaborated on countless go-to-market (GTM) digitization projects over the years. We've also stepped in to conduct course correction for digitization projects that have stalled or gone awry. Here, we’ve compiled the lessons learned to create a best-practice guide that will help you:

- Accurately identify your specific GTM challenges

- Provide in-depth solutions on how to address them

- Understand technology's role in shaping your present GTM strategy

- And how technology can help you achieve future business goals

Once you've gone through the fundamentals of sales digitization, you will be able to learn how to:

- Uncover hidden potential in the current business

- Sidestep potential barriers to digitalization success

- Solve current problems in your digital initiatives

Table of contents

- State of manufacturing sales

- Connecting silos in data and function

- Start your GTM transformation on the right foot

- Forming the bridge between business and market

- Overview of digital maturity stages

- Uncover the path to digital transformation success

- Breaking down the barriers to GTM digitization success

- Practical steps to progressing in digital maturity

- Getting the right digital sales platform pays off

- Mastering Digital Sales needs to happen now

Download the full guide here for offline reading or to build a case for digitizing your organization's go-to-market approach.

State of manufacturing sales today

Manufacturers know that economic conditions have changed drastically in the past five years. Change is the only constant, however, and taking a wait-and-see attitude leads to uncertainty with potentially irreversible consequences.

Remember: The opportunities and pressures your customers face have changed too.

Consolidation, supply chain disruptions, increasing speed of business, rising customer demands, and consumerization of B2B are all contributing to customers seeking out new partnerships that create more value. Right now, your current and potential customers are actively seeking out vendors with a faster, more streamlined buying process. The kind that can only be powered by sales automation. Customers want smoother transactions. Transparent, instantaneous feedback. Well-crafted user experiences that are as good as, or better than, those of B2C online shopping.

While some see risk in transformation, smart manufacturers like you see opportunity.

Manufacturers and suppliers must keep pace with emerging technologies or risk losing deals to competitors and a further weakening of their established networks. Smart sales automation replaces manual traditional processes and instantly addresses the speed and efficiency aspects of sales.

At the same time, knowledge digitization addresses a new challenge: the global shortage of sales and engineering staff with valuable domain expertise. This way, manufacturers can effectively fill knowledge gaps with data straight from the business. That, in turn, allows the business to remain competitive on price, service, and delivery.

By digitizing manufacturing sales, your business gets better at delivering outcomes.

Leading manufacturers are already investing heavily in a digitized sales approach. They realize that their clients want to buy customized products but aren't interested in a complex buying journey that takes weeks or months to complete. Today's B2B customer wants a buying journey that is fast, convenient, and transparent so they can get back to focus on their business. In short, your go-to-market approach will decide your company's success.

If you leave sales digitization in the too-hard-basket, that's exactly where prospects will put your business.

Connecting silos in data and function

Getting GTM digitization right has a profound impact on the entire business. The business improvements go far beyond sales. Most In Mind Cloud customers also see improvements in customer experience and their overall digital transformation strategy.

That makes GTM digitization everyone’s business. The CEO and leaders in charge of revenue (CRO) and growth (CGO), need to pay as much attention to the GTM digitization strategy as the leaders in charge of IT (CIO) or digital transformation (DXO).

Success depends on connecting data silos as much as functional silos. Cross-silo leadership in your manufacturing business will enable your GTM digitization to deliver its full potential—to increase sales, win customer loyalty, and ensure overall improvements to your B2B manufacturing business.

Who should read this guide

- Business leaders looking for manufacturing business efficiencies and revenue growth opportunities

- Sales leaders seeking improved sales outcomes, productivity, and performance

- Customer experience leaders who want to ensure customer retention while upselling and cross-selling

- Digital transformation leaders in charge of digitizing manufacturing knowledge to enable sales automation

- Information technology leaders who want the benefits of a fully digitized end-to-end sales process with minimal disruption

Start your GTM transformation on the right foot

The ideal starting point for GTM transformation is to scrutinize your customers' buying journey.

You want to help them reach their goal as fast and as easily as possible. Begin with some key questions to help keep things in perspective:

Questions that keep your go-to-market digitization on track

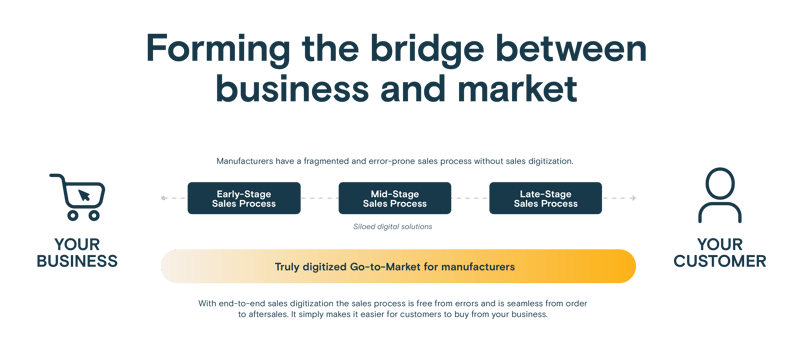

Forming the bridge between business and market

Most manufacturers have already started using digital solutions in their GTM approach. Some might have a basic CRM that works as a digital Rolodex. They might have a simple eCommerce tool that acts as a catalog for spare parts and consumables. They may even have a sophisticated spreadsheet system that automatically calculates costs and prices based on regular data updates. With end-to-end sales digitization, the sales process is free from errors and is seamless from order to aftersales. It simply makes it easier for customers to buy from your business.

Siloed digital solutions are simply stopgap measures.

A truly digitized GTM—or sales process—breaks down the data siloes between each sales function. A manufacturer’s data generates more value when it flows freely between production, ERP, CRM, quoting tools (CPQ), and your customer or partner-facing portal. When that happens, a bridge is formed between the customer, partner, and the manufacturing business. Through this digital bridge, your buyers or partners can more easily access your business to get what they need; to purchase your unique manufacturing solutions without friction.

With digitized GTM, selling becomes easier. All stakeholders and customer touchpoints are interconnected with your business. Sales teams can instantly use real-time ERP prices (made 100% accurate by real-time costs) to create quotes on the fly. Customers and partners can log in through your online sales portal to browse, compare, configure, buy, and pay for entire solutions—with minimum involvement of your sales teams.

Spare parts and consumables sell themselves because your customers can order and buy whenever they need to. When buying becomes this easy, your customers will thank you by coming back.

The true potential of a digitized manufacturing GTM is to get your business to become digitally mature. This new status quo can help manufacturers reduce their reliance on external marketplace channels and vastly improve the customer’s buying journey. According to research by Gartner & Forrester, digitally mature businesses—in all sectors (including manufacturing) outperform their competitors at every turn.

True end-to-end digitization of your go-to-market through a single platform offers a better buying experience than one that comprises disparate, stop-gap solutions

Digital maturity is market dominance. Where does your business stand?

In the past decade, numerous studies have shown that digitally mature businesses are more profitable—and more likely to dominate the market. But digital maturity is more than just the number in your technology stack. It’s a measure of how well your digital tools are interconnected to create value from your data. Manual methods like spreadsheets or paper and storing data in a rudimentary ERP no longer cut it.

Some businesses may have upgraded to more advanced ERP systems or have basic CRM systems, but if their data is siloed, they’re cut off from the potential benefits of digitization. The silver lining for businesses earlier in their journey towards digital maturity is this: Cloud computing can help leapfrog the pain and disruption of digitization by transforming entire processes.

Targeting the whole GTM process benefits businesses immediately through an interconnected sales process. Cloud connectivity lets sales-relevant data become accessible in real-time by embedded sales tools like CPQ, CRM, or eCommerce. GTM digitization can be used to completely automate smaller or recurring deals like those in aftersales.

Manufacturers get a 360-degree view of every account and can perform accurate forecasts. Customer engagements are made with the most precise, margin-protected costs and prices from the ERP. There is no one-size-fits-all approach. If you’re looking to transform your GTM, you must strategize and prioritize according to your current digital maturity level. Here, we’ve identified five GTM maturity levels for manufacturers.

GTM maturity stage 1: Pre-Digital

Manufacturers in this category are unsure of the value a digital GTM can deliver to the business and have no plans to digitize their sales.

What your sales situation is like:

- Digital strategy: Ad-hoc IT planning and disparate data sources

- Digital intelligence: Excel or manual reports for business intel

- Process: Manual systems and rudimentary ERP

- Customer experience: Limited customer KPIs and reactive problem-solving

DM 1Pre-digital Ad-hoc IT planning & disparate data sources |

DM2Digitally Reactive Clearer digital GTM priorities and first purposeful system implementations |

DM3Digitally Purposeful Documented IT plan and budgets |

DM4Digitally Optimized Strategic alignment of IT |

DM5Digitally Strategic Digital-led business strategy |

| Reduce costs > Increase sales efficiency > Increase revenue > Competitive advantage |

GTM maturity stage 2: Digitally Reactive

Manufacturers in this category understand the need for digital GTM, but have taken little to no action to digitize their sales process.

What your sales situation is like:

- Digital strategy: Clearer digital GTM priorities and first purposeful system implementations

- Digital intelligence: Customized reports

- Process: Siloed ERP, CRM, spreadsheets

- Customer experience: A documented voice of the customer and first processes for recurring problems

DM 1Pre-digital Ad-hoc IT planning & disparate data sources |

DM2Digitally Reactive Clearer digital GTM priorities and first purposeful system implementations |

DM3Digitally Purposeful Documented IT plan and budgets |

DM4Digitally Optimized Strategic alignment of IT |

DM5Digitally Strategic Digital-led business strategy |

| Reduce costs > Increase sales efficiency > Increase revenue > Competitive advantage |

GTM maturity stage 3: Digitally Purposeful

Manufacturers in this category have started the digital transformation journey of their GTM via the digitization of several processes in their GTM.

What your sales situation is like:

- Digital strategy: Documented IT plan and budgets

- Digital intelligence: BI dashboards & custom reports

- Process: Basic automation and integration efforts for CRM or CPQ

- Customer experience: Customer lifecycle management and active prevention of issues

DM 1Pre-digital Ad-hoc IT planning & disparate data sources |

DM2Digitally Reactive Clearer digital GTM priorities and first purposeful system implementations |

DM3Digitally Purposeful Documented IT plan and budgets |

DM4Digitally Optimized Strategic alignment of IT |

DM5Digitally Strategic Digital-led business strategy |

| Reduce costs > Increase sales efficiency > Increase revenue > Competitive advantage |

GTM maturity stage 4: Digitally Optimized

Manufacturers in this category are in the middle of the digital transformation journey of their GTM process, but are seeing limited results from their initiatives

What your sales situation is like:

- Digital strategy: Strategic alignment of IT and business

- Digital intelligence: Prescriptive analytics

- Process: Advanced automation and CRM, CPQ, Commerce integration

- Customer experience: A business strategy centered around Customer Experience

DM 1Pre-digital Ad-hoc IT planning & disparate data sources |

DM2Digitally Reactive Clearer digital GTM priorities and first purposeful system implementations |

DM3Digitally Purposeful Documented IT plan and budgets |

DM4Digitally Optimized Strategic alignment of IT |

DM5Digitally Strategic Digital-led business strategy |

| Reduce costs > Increase sales efficiency > Increase revenue > Competitive advantage |

GTM maturity stage 5: Digitally Strategic

Manufacturers in this category have successfully transformed their GTM into one that is driven by data derived from AI-based analytics.

What your sales situation is like:

- Digital strategy: Digitally-led business strategy

- Digital intelligence: AI-based analytics

- Process: End-to-End global and strategically scalable process automation

- Customer experience: Customer-centric DNA

DM 1Pre-digital Ad-hoc IT planning & disparate data sources |

DM2Digitally Reactive Clearer digital GTM priorities and first purposeful system implementations |

DM3Digitally Purposeful Documented IT plan and budgets |

DM4Digitally Optimized Strategic alignment of IT |

DM5Digitally Strategic Digital-led business strategy |

| Reduce costs > Increase sales efficiency > Increase revenue > Competitive advantage |

Uncover the path to digital transformation success

Digital transformation is essential to stay relevant. However, most initiatives do not deliver according to expectations. According to analyst firm McKinsey, approximately 80% of businesses fail at digital transformation. In the case of digital GTM, manufacturers are failing at implementing CRM, CPQ, and eCommerce. The most common cause of failure is that manufacturers start GTM digitization with a generic software and hardware solution.

Generic tools are built for all industries, yet do not fit any single business. Manufacturers choosing a generic software route often get stuck in a vicious cycle of compromise, consultations, and customization. You likely know someone in your network that's hemorrhaging time and money on consultants just to arrive at the minimum viable product. There is no guarantee that the software lives up to expectations of increased revenue, costs saved, and competitive advantages gained.

Start with the right approach, followed by the right software

Software matters, sure. But success in GTM digitization needs to start with the right approach: customer-centricity. With a customer-centric mindset, the path toward GTM digitization becomes clearer.

We must begin by asking:

1. How can I help my customers buy more quickly and easily?

2. How can I make sure pricing is fair, attractive and profitable?

3. How do I stay one step ahead of my customers’ needs?

These questions are simple, but they can lead manufacturers to insights on what goals they are looking to achieve, rather than getting caught up in what features are available. For example, helping customers buy faster and easier could mean having the ability to use an e-commerce portal for customer self-selection to reduce sales friction.

Making prices fair and profitable could mean using a CPQ (Configure-Price-Quote) to generate accurate prices based on real-time global pricing from your ERP. Staying a step ahead of customers is possible with a CRM that integrates with your sales tools, helping glean buying insights and create accurate forecasts.

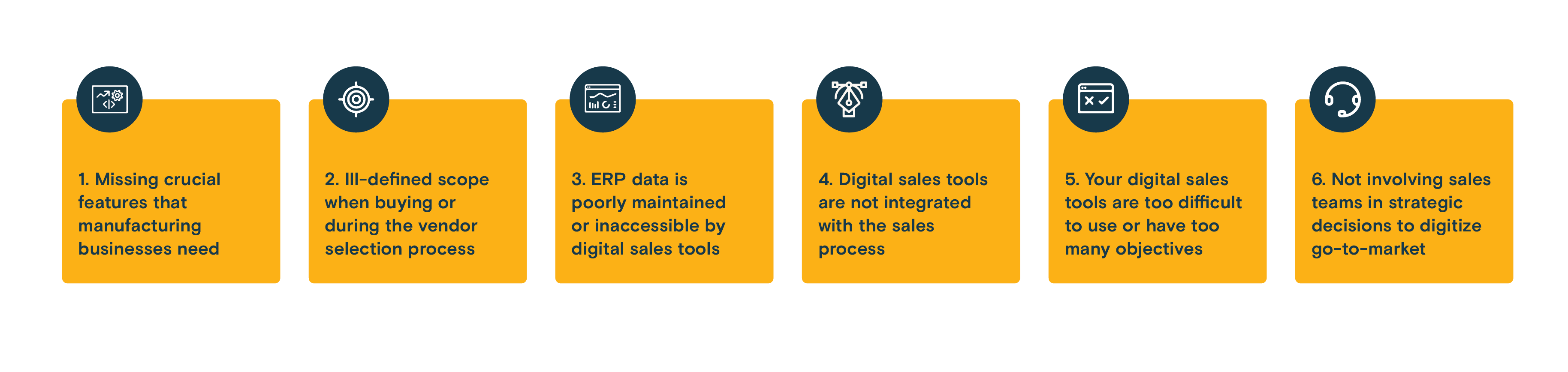

Breaking down the barriers to GTM digitization success

One factor that contributes to lagging GTM digitization is plugging technology gaps with standalone software. Short-term, stopgap solutions will rarely bring about the maximum potential of an integrated system. While a quick fix might appear attractive, manufacturers must identify the barriers and qualify the potential of each software solution.

These are the common barriers that manufacturers face when they digitize their sales process

Common barriers to getting CPQ, CRM, eCommerce, and GTM digitization right

Following are just some of the pitfalls to be aware of when strategizing a digital go-to-market approach. To get the full benefits of a digitized GTM, manufacturers should outline what their goals are for the system as a whole, rather than the features that the developer is preaching as the solution.

- Missing crucial features that manufacturing businesses need

- Poorly defined scope when buying or during the vendor selection process

- ERP data is poorly maintained or inaccessible by digital sales tools

- Digital sales tools are not integrated with the sales process

- Your digital sales tools are too difficult to use or have too many objectives

- Not involving sales teams in strategic decisions to digitize go-to-market

Barrier 1: Missing crucial features that manufacturing businesses need

Most of the solutions available in the market are industry-generic and will require customization to fit your unique business requirements. Take CPQ, for example. Not all CPQ software is capable of CAD configuration, costing simulation, or BOM creation in the ERP straight out of the box. With generic software, adding any of these features often requires excessive costs.

There are times when generic software may not even have user-level features (e.g., drag and drop line items) or usability enhancements (e.g., user experience design) to help users work more efficiently.

Barrier 2: Ill-defined scope when buying or during the vendor selection process

A common mistake for manufacturers is selecting software to suit their current business practices instead of considering what the future looks like. The result is software that solves an immediate problem while leaving them just as stuck when market demands change. An example is

a CPQ tuned for a current portfolio that charges the manufacturer when adding new product lines.

Within the eCommerce realm, a product gallery may be ‘just a website’— instead of connecting it to real-time product data that improves the buying experience. In the case of CRM, another misstep is creating a digital Rolodex alone that won’t provide insights into buying behavior for accurate forecasts.

Barrier 3: ERP data is poorly maintained or inaccessible by digital sales tools

This barrier is by far the most damaging for manufacturing sales. When your ERP data is not maintained, bad data quality can cause errors to pile up. Bad data, in turn, renders your digital sales tools unreliable. The software becomes something that your sales team avoid rather than use to improve sales.

On the other hand, digital sales tools with no access to ERP data cannot reach their full potential. Manually updating data on CPQ, CRM, or eCommerce platforms is an unnecessary burden on sales teams, causing them to avoid digital sales tools altogether and taking your digital GTM strategy back to square one.

Barrier 4: Digital sales tools are not integrated with the sales process

When sales tools are siloed, the overall effect of a digitized GTM becomes greatly diminished. Without data flow, each digital tool requires tedious manual updates to stay relevant. Using a manufacturer's aftersales and dealer portal as an example, having integrated data gives a high level of transparency and trust to all stakeholders.

With native integration, internal sales can get deep insights into online buying behavior that helps them uncover upselling or cross-selling opportunities. Third-party sales can easily log in to configure solutions using the latest, automatically calculated, dealer-specific prices.

Customers can browse and buy spare parts at their convenience and receive updates on arrival times. All of the scenarios are part of a streamlined sales process empowered by GTM digitization. However, they are only possible through deep integration between individual digital sales tools and your ERP.

Barrier 5: Your digital sales tools are too difficult to use or have too many objectives

Digital sales tools can have the potential to transform how your business works completely. They should be built to handle the complexity of your manufacturing business and sales process but also designed to factor in the human element.

In an effort to save on costs short term, some manufacturers may dismiss usability features—like smart guidance, intelligent selling, built-in collaboration features, and customizable, user-friendly interfaces as options that may only be needed ‘down the track.’ Perhaps equally as frustrating to teams is being given too many new tools at one time that complicate processes.

When the change is too great or when the software is too complicated to use, users easily get overwhelmed and revert to familiar but obsolete methods. When that happens, the long-term adoption of software is affected, and so too will be the digital GTM strategy.

Barrier 6: Not involving sales teams in strategic decisions to digitize go-to-market

Turnkey solutions are one of the most efficient ways to digitize a GTM approach. However, when the sales team—the direct beneficiaries of a digitized GTM—are not involved in the decision-making process, problems ensue.

The result can be a digital GTM solution that meets IT requirements but doesn’t support sales teams in reaching their key goal: increasing sales. Your sales team will be quick to point out where ‘solutions’ actually create more busyness like manual data entry.

It might be the case that a chosen digital GTM portal could compete against direct sales or be used to solely track sales performance—without actually helping sales reps sell more and better. These scenarios could lead to sales reps withholding opportunities or information from the digital GTM system.

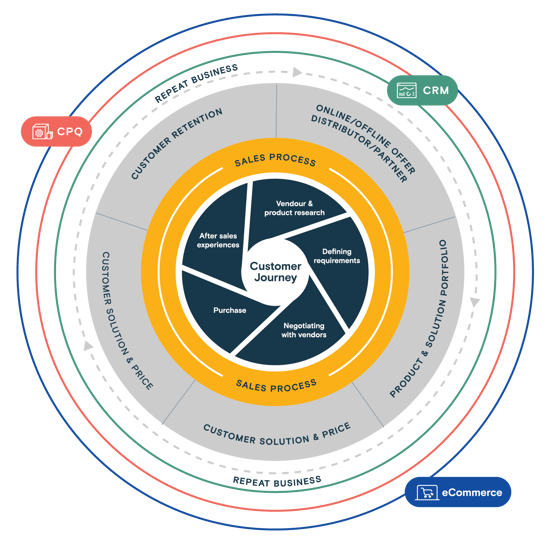

Anatomy of a successful manufacturing go-to-market approach

Aligning the sales process with the customer journey enables some powerful benefits for any manufacturing business

An aligned process makes it easy for customers to buy. At the same time, selling becomes easier for your business. Customers who have a good buying experience refer you and come back as repeat business. This scenario is powered by connecting three core technologies: CPQ, CRM, and eCommerce.

CPQ + CRM + eCommerce = the engine behind your GTM

CPQ, CRM, and eCommerce technologies are not new to the market. Neither are they exclusive to the manufacturing industry. However, for them to power your manufacturing GTM, In Mind Cloud makes them work seamlessly together through a two-way integration with your ERP. This access allows for seamless data exchange—use product data from your ERP, and update the ERP with new order data.

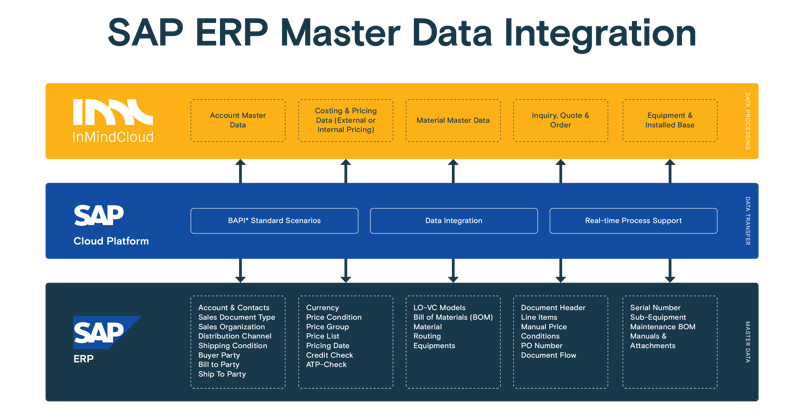

SAP ERP Master Data Integration

The ability to read data lets your digital GTM use real-time ERP data to perform functions like generating quotes using current prices or letting customers configure complex products and solutions entirely through your e-commerce portal. The ability to write data means the system can update your ERP with order data, which can then be used by production to start the manufacturing process or used to form a highly accurate overview of customer buying behavior.

How a Digital Sales Platform can be integrated with existing back end systems

What is go-to-market digitization success?

Data flowing between each tool and your ERP forms the foundation of your GTM strategy.

With data, each tool—whether it’s your CPQ, CRM, or eCommerce portal—helps your business achieve specific goals. Each goal you achieve is a win for the business. Your business can achieve outcomes measured on a larger scale when you put them together. With a digital GTM, your business benefits from:

- An increase in sales efficiency and productivity through superior sales automation and seamless collaboration between teams

- Competitive advantages achieved through higher customer retention, market agility, and fast innovation-to-market

- Reduction in error-related costs incurred during the sales process, such as misconfigurations, costing inaccuracies, order errors, etc.

- Increased revenue from better win rates, fewer lost deals, channel expansion, and retained customer follow-up sales

How focusing on CPQ can transform your manufacturing business

| Offer the convenience of a virtual showroom | Automated accuracy that ensures profitability | Streamline sales workflow to reach customers first |

| An integrated CPQ lets manufacturers create virtual showrooms that display real-time data. Customers and third-party sales can access detailed product information, get buying guidance, compare variants, check inventory levels, configure, and buy without physical interaction. | Manufacturing pricing is highly complex. A CPQ helps manage the huge number of pricing factors needed for pricing accuracy. Margin protection capabilities are also built-in and can be defined by the customer to ensure the best margins. | Quote accuracy is dependent on input from several stakeholders and various departments. With workflow automation, quotes can be made and approved in one day instead of the weeks it used to take. This agility gives manufacturers a higher chance of reaching customers before their competitors. |

How focusing on eCommerce can transform your manufacturing business

| Get a faster, easier way to reach and sell to customers | Manage your global sales network from one platform | Offer the best possible aftersales experience to customers |

| In a global marketplace, there will always be a customer ready to buy from your business. eCommerce lets you stay open and accessible 24/7 to customers who want to reach you. At the same time, innovations and new promotions can be launched and be ready for customers to buy in days instead of weeks or months. |

Your eCommerce portal is also the gateway to your business for partners, distributors, and dealers. It lets you extend advanced sales functions to them and gets them as productive and efficient as your sales team. In parallel, your business maintains full transparency and control over how your products and solutions are represented and sold. |

Aftersales can be a significant revenue source for manufacturers. It is also a key pillar of customer service. With eCommerce, you make aftersales buying of spare parts and consumables, product inquiries, and services available 24/7. It can be a fully or partially automated way to close deals with customers familiar with your business so that your sales team can focus on engaging new high-value customers. |

How focusing on a CRM can transform your manufacturing business

| Deeper understanding of customers that drive stronger relationships | Follow-up and respond before your competitors can react | Expand your reach with a fully managed sales network |

| An integrated CRM helps you understand everything about the customer. This 360-degree overview provides valuable insights that help you anticipate the customer’s every need and capitalize on hidden upselling and cross-selling opportunities. |

In manufacturing, speed is a key success factor. With CPQ and eCommerce integration, your CRM lets you react quickly to changes in customer needs or behavior. Sales can respond instantly to eCommerce portal queries with highly accurate quotes for products or solutions on the fly. |

Channel sales can be a powerful way to expand your reach to new markets. But managing it can be challenging. Some manufacturers use a sales system with embedded CRM integrated with the entire manufacturing business—and extend it to external sales channels. This way, no matter the channel your customers engage with, they only see a single brand—yours. |

Practical steps to progressing in digital maturity

Step 1 - Identify your GTM digitization goals

To begin your GTM digitization journey, it’s imperative that all stakeholders understand the capabilities and limitations of tools and the goals of the manufacturing business. For example, the most basic CPQ tools can be used simply to price configurated products. However, manufacturers are now using CPQ to streamline the entire sales process from lead to production.

A CRM can be so much more than a database of names and emails. Manufacturers use it to provide a 360-degree overview of customers’ buying behavior and deliver highly accurate forecasts that can guide your business through the next disruption. Combined with CRM and QPQ, eCommerce becomes a digital gateway to the manufacturing business that’s open and available 24/7 for customers and third-party sales.

The scope of each tool has evolved to match a manufacturer's need to sell complex products, solutions, and the industry the manufacturer serves.

Here are some powerful business outcomes with manufacturing-focused Digital Sales tools

| CPQ Outcomes | Consistently accurate quotes | Best-match customer solutions | Exceed buyer expectations across channels |

| How a CPQ powers these outcomes |

|

|

|

| eCommerce | Offer a shorter path to deal completion | Fully manage global sales channels | Provide a powerful new sales channel |

| How eCommerce powers these outcomes |

|

|

|

| CRM | Enable success across all channels | Ensure future scalability | Connect a global salesforce |

| How a CRM powers these outcomes |

|

|

|

Step 2 - Understand what your top digital sales users need

Your GTM strategy has to benefit more than one department. And with an integrated solution, the whole business benefits. Marketing can use CRM insights and eCommerce to push out promotions in minutes. Engineering can use your CPQ to design and collaborate on complex solutions using built-in CAD tools. Customer Service can use the CRM to stay one step ahead of customer needs or eCommerce to upsell and cross-sell spare parts and consumables. Identifying these users early can help you define a clear and concise digital GTM strategy.

Simply put, the benefits of a Digital Sales Platform can extend far beyond the sales team.

Determine your Digital Sales (CPQ, CRM, eCommerce) requirements with our interactive Manufacturing Sales Software Comparison Checklist. Just answer a few questions, and we'll send you a personalized checklist that you can use to find the ideal Digital Sales tools for your manufacturing business.

Step 3 - Define your manufacturing digital sales requirements

Each manufacturing business has its unique requirements when it comes to digital sales. Your manufacturing business may be focused on improving pricing accuracy, providing a fully digital buying experience, or elevating forecast accuracy to cope with disruptions. To reach the right outcomes for the business, you need to identify the right capabilities. If this step is not done judiciously, you may end up with an expensive do-it-all solution that does not deliver results.

Here are questions worth asking when building your Digital Sales requirements list:

- How will your digital sales solution improve your current sales process?

- Which systems and digital tools does it need to connect to and enhance?

- Is the digital sales solution scalable enough for your growth strategy?

- How can it improve the customer’s buying journey with your business?

- Is it easy for non-technical users to use? Does it help them work better?

- Does it integrate with all the digital tools your engineering team uses?

The most important question:

Do the Digital Sales tools you have shortlisted help transform the organization's go-to-market strategy and help you reach your business goals?

Step 4 - Send your list of goals and preferred features to potential vendors

Once you've narrowed down goals and necessary capabilities, it's time to form a selection team. This team will ideally comprise key decision-makers in the buying process and, of course, future platform users. Teams expected to use the digital sales solution most would be your most valuable input sources.

So be sure to get pre-implementation feedback from your sales team (sales reps and sales ops), engineering, aftersales, and marketing. Once you have identified the key capabilities in a requirements checklist, you can easily turn that checklist into a compliance document and send it to potential Digital Sales solution vendors. Your selection team would then narrow down their choices and start negotiations.

Make sure you compare Apples with Apples

Note that pricing structures will differ between vendors. Some may charge by integration complexity, the volume of transactions, or the number of users. In order to compare solutions, opt for businesses with transparent pricing and business conditions, noting whether there are any ‘lock-in’ terms. Once the vendor has been chosen, the selection team can begin getting buy-in from all stakeholders involved in the Digital Sales solution buying process.

Get a Digital Sales Software Comparison Checklist here. Simply answer a few questions, and we'll send you a checklist that's customized to your business.

Getting the right Digital Sales Platform pays off

For manufacturers, the goal is to find a turnkey solution ready-made to deal with the business's complexities, ideally from a provider which is deeply involved in the manufacturing sector. Only a manufacturing specialist will truly understand your sales challenges and design solutions to overcome them.

A trusted partner with manufacturing expertise will know what success looks like and guide your business on the right path towards a higher digital maturity. With the right partner on board, your GTM digitization journey will be able to lead to some tangible results along with tremendous IT savings. Here's an example of what our customers achieved with the In Mind Cloud Digital Sales Platform.

| How you can accelerate growth with a Digital Sales Platform |

|

Increase sales efficiency

|

Reduce costs

|

|

Competittive advantage

|

Increase revenue

|

Digital transformation of your go-to-market approach is not going to happen overnight. That said, it can be accelerated with a vendor that has a deep understanding of the manufacturing industry. Many of our customers complete implementation within six months and report significant IT savings and ROI within the first year. These are powerful results that In Mind Cloud strives to help all manufacturers achieve.

Find out more about how your business can achieve the same results with an advanced Digital Sales Platform built for the complexities of manufacturing sales. Simply book a no-obligation consultation with one of our manufacturing experts for a quick walkthrough of the In Mind Cloud Digital Sales Platform. You can also download a digital copy of the Roadmap to Digital Go-to-Market Success for offline reading, or for sharing with your colleagues.

Deutsch

Deutsch