What is manufacturing sales?

Manufacturing sales happens when a manufacturer sells their products—finished goods from raw materials or components. Well, at least that was an appropriate definition pre-Industry 4.0, pre-digitalization, and pre-consumerization.

Nowadays, manufacturing sales needs to do so much more: Smart manufacturing methods drive rapid innovation across all verticals, 24/7 online sales are becoming the norm in the industry, and manufacturers are making every effort to adapt to B2C expectation levels.

Ask any manufacturer what he thinks of manufacturing sales; he’d reply to your question with one word: Complex.

Manufacturing Sales Handbook: Everything you need to know about selling in the manufacturing industry

What makes manufacturing sales complex?

For the answer to become evident, you need to understand the critical difference between B2B (business-to-business) and B2C (business-to-consumer) sales. In B2C, a company sells to a consumer—for example, Tesla sells a car to your neighbor. In B2B, a company sells to another business—for example, a manufacturer of steering systems sells to Tesla.

In the first case, the transaction is relatively straightforward. It involves one or very few decision-makers, is driven by personal expectations, and is sold through a price that is known and, in comparison, small.

In the second case, the business buying the product—Tesla in our previous example—looks for manufacturers that meet their technical requirements for a specific component of their vehicle. They then start a selection process that involves multiple suppliers of the same component submitting their proposals.

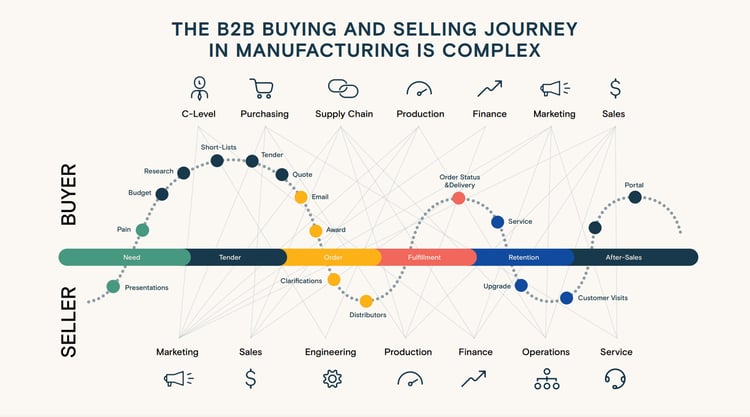

This highly complex journey involves multiple stakeholders from both sides and can take months to complete

Throughout this process, various stakeholders from Tesla can be involved in the requirements setting, budgeting, and research process.

Meanwhile, the suppliers need to engage in a series of tasks. It starts from gathering requirements and using the information gathered to begin design, engineering, calculations, part configurations, material and production simulations, pricing, and ultimately creating a tender document.

This process involves salespeople, engineers, material and production experts, procurement, and middle-management decision-makers. The entire quoting process can take up to several weeks and incur a high cost of sales.

The B2B buying and selling journey in manufacturing is complex

At this point, we have not even painted a complete picture of this journey. Often, negotiations or corrections can easily send this process into a repeat loop before the customer even buys. And when the buying business makes the final order, another set of complexities come into play. Factors such as labor dynamics, material costs, or any unforeseen production circumstances could threaten the successful delivery of the product or manufacturing solution.

You can conclude that in B2B manufacturing sales, the buying journey and the selling process are a winding path of multiple dependencies. It involves a high number of stakeholders (6-10) and carries significant risk from errors or delays for both the buying business and the manufacturer.

Having a complicated buying process in the manufacturing industry was accepted as the norm. But research has shown that B2B enterprises, like manufacturers, need to overcome it in order to recover during economic downturns.

What are the strategies of manufacturing market leaders?

Manufacturers leading the market today have developed strategies that help them stay ahead. They overcome market challenges by constantly adapting how they sell and operate their businesses so they can solidify their market position and mitigate the risk of revenue loss.

In recent years, market leaders are starting to focus on digitalizing sales. This ensures their sales process is as agile and responsive as the rest of the business that has been updated with Industry 4.0 technology.

The goal here is to meet the growing consumerist demand from B2B decision-makers. They expect a flawless buying journey, from RFQ to delivery and beyond. According to PWC, 86% of B2B buyers are willing to pay MORE for an excellent customer experience.

And since the COVID-19 pandemic, the definition of an excellent customer experience is pointing towards digital self-serve models. This is partly due to COVID-19 restrictions, but B2B buyers are also discovering (and demanding) the convenience and efficiency of buying online.

Leading manufacturers are beginning to understand more about the critical role a Digital Sales Platform can play in their business. According to a study by McKinsey, digital sales can improve the win rate of offers by 20 to 40 percent, while costs-to-serve drop by up to 50 percent.

That’s not to say digital sales will solve all the challenges manufacturers face. Still, it can certainly help with the top 4 challenges your manufacturing business will face in the coming years.

To read more about manufacturing sales and its nuances, download our latest Manufacturing Sales Handbook. In this ebook, we help you understand everything there is to know about manufacturing sales, and how digital can potentially accelerate your sales cycle.

This blog post is part of an article that was first published on the G2 blog

Deutsch

Deutsch