Electrical power is the lifeblood of your business. You produce batteries, sensors, electrical wiring, lighting equipment or motors, generators, or transformers to keep electricity flowing for your customers. Then you'd fit into the category of electrical equipment and electrical components manufacturers and we know your sales challenges quite well:

Your business probably depends on efficient operations, economies of scale in purchasing materials and production, and of course, technological expertise. In addition, you try hard to balance costs versus customer requirements and short innovation cycles— all the while keeping a close eye on margins.

Let us have a closer look at where are weaknesses, risks but also the chances and opportunities of a business in the Electrical Equipment Industry.

5+1 types of manufacturing that define sales in the electrical equipment sector

We know that manufacturers in your sector employ different sales strategies that help them navigate the tricky market conditions. However, these strategies can also be influenced by the chosen business model. Here is a brief description of the various business models used to meet market demand:

Make-to-stock (MTS) in electrical equipment

Why this model is used

- Demand for products is predictable and easily forecasted

How it works for electrical equipment manufacturers

- Expends capital to produce goods in advance

- Capital is bound to the finished goods until they are sold

- Incoming orders use existing inventory, keeping lead times low

Ideal for manufacturing products that:

- Are mass-produced at low costs and high quantities

- Are readily available with extremely low lead times

- Require little to no engineering and design

Make-to-order (MTO) in electrical equipment

Why this model is used

- Standard products and specifications are clearly defined

How it works for electrical equipment manufacturers

- Products are only produced when orders are received

- Lowers risks of overproduction for manufacturer

- Increased production costs and lead times

Ideal for manufacturing products that:

- Cost more, but can be produced in large quantities upon order

- Require some engineering and design

- Can be manufactured and delivered fairly quickly

Make-to-assemble (MTA)/Assemble-to-order (ATO) in electrical equipment

Why this model is used

- A flexible model that allows for speed and reduced waste

How it works for electrical equipment manufacturers

- Parts and components are pre-produced

- Assembly only happens when orders are received

- The manufacturer is ready to fulfill orders instantly

Ideal for manufacturing products that:

- Are ordered in lower quantities

- Requires some engineering and design

- Do not offer options to configure

Configure-to-order (CTO) in electrical equipment

Why this model is used

- Enables mass customization and faster response time

How it works for electrical equipment manufacturers

- Products configured and assembled according to requirements

- Standard subassemblies made-to-stock and instantly available

- Final assembly is postponed until the order comes in

Ideal for manufacturing products that:

- Are ordered in lower quantities

- Offer a large number of configuration options

- Requires moderate engineering and design

Engineer-to-order (ETO) in electrical equipment

Why this model is used

- Extremely complex or specialized product or solution

How it works for electrical equipment manufacturers

- Project-based work starts only when order is received

- Comprises a long timeline of design, engineering, and production

- Final product is engineered according to unique specifications

Ideal for manufacturing products that:

- Are ordered in low quantities

- Requires a high degree of engineering and design

- Has highly specific customer requirements

Manufacturing-as-a-Service (MaaS)

in electrical equipment

Why this model is used

- Highly optimized by emerging Industry 4.0 technology

- Fast, low-cost, high-quality production of almost any product

- Resource consumption can be kept under tight control

How it works for electrical equipment manufacturers

- The manufacturer is equipped to produce anything a customer wants

- Uses shared infrastructure to reduce costs and improve quality

- Process expertise instead of products is sold to the customer

Ideal for manufacturing products that:

- Are highly innovative and new to the market

- Require high customization or personalization

- Needs to be low cost even in low quantities

- Has fast time-to-market requirements

Different manufacturing complexities in electrical equipment sales

As a manufacturer in the electrical equipment industry, you often use a mix of more than one manufacturing model. That makes sales scenarios extremely broad. You can offer customers stocked products, the option of modifying existing designs to fit their purposes, the configuration of complete solutions, or the production of custom design products.

Giving customers more ways to buy is an advantage. However, for every manufacturing model applied, the disadvantages you have to manage can start to pile up. If you use more than one model the likelihood of benefiting from a solution that ensures precise forecasting, fast configuration, and customer (partner and distributor) self-serve capabilities increases massively.

In other words, you should think about digitalizing the sales process to make it easy for customers, partners, dealers, or distributors to buy your products or solutions.

However, getting these features is not just buying best-of-breed solutions from multiple IT service providers. Going this route often leads to spending far more resources than you plan to. Integrating solutions from various vendors can take months, if not years.

And even then, can lead to an unsatisfactory outcome - for you and your customers.

That’s because solutions from leading IT solution vendors are not built with manufacturing in mind. To get the solutions to fit your electrical equipment manufacturing business, you would need to spend time (and money) tweaking the software and adding the functionalities you need.

Instead, you would observe much better results if you went for a solution built from the ground up for electrical equipment manufacturers. Such a specialized digital sales solution comes with the features you need out-of-the-box and can support all manufacturing models through one platform.

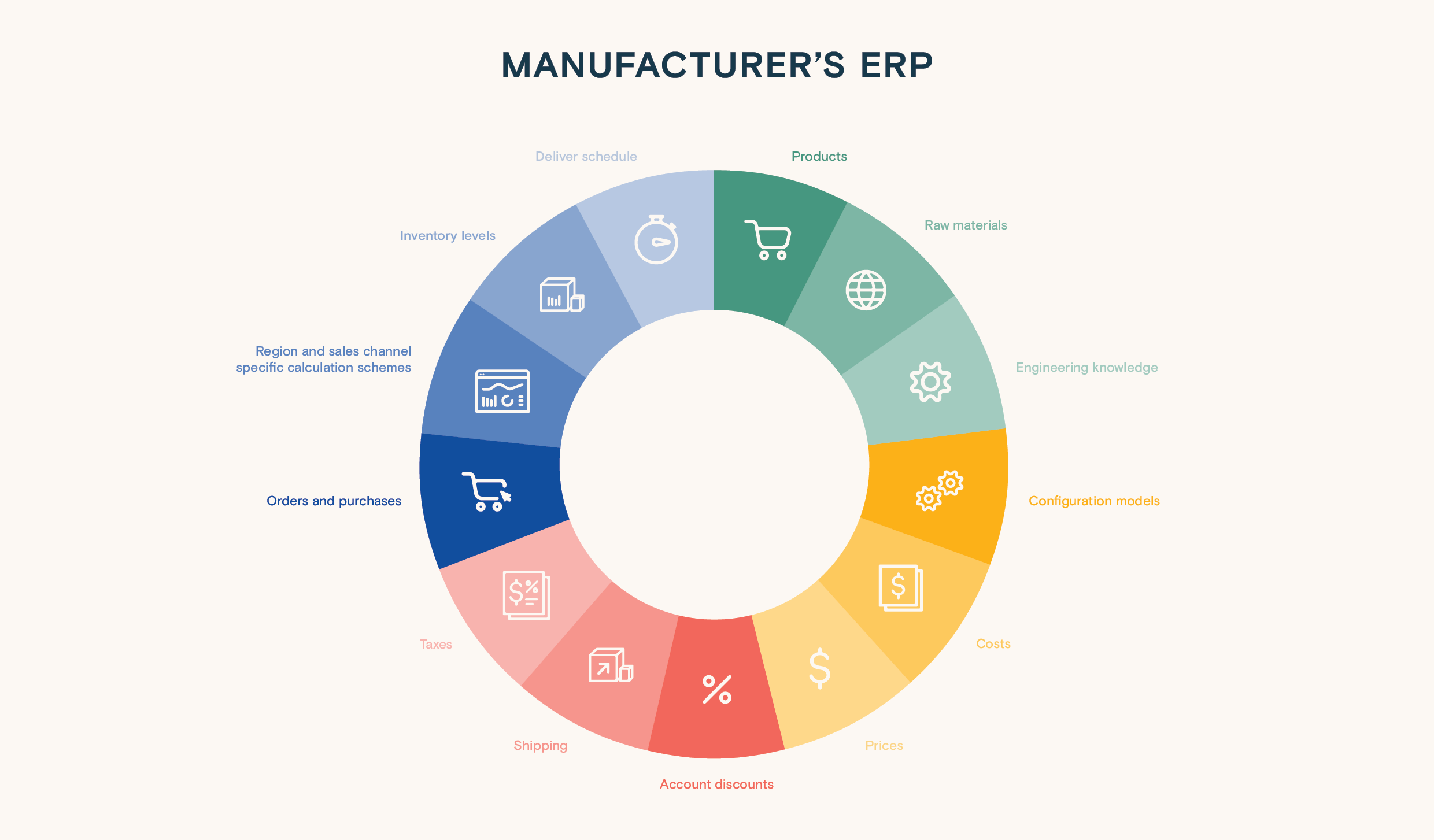

Valuable sales data Electrical Equipment manufacturers need to extract from their ERP

A modern digital sales platform can integrate seamlessly with your ERP, and extract relevant sales data to support your end-to-end sales needs with:

- Complex configuration & pricing calculations

- Customer management & accurate forecasting

- Online sales and channel management

To find out more about how a modern manufacturing-focused digital sales platform can transform your sales process, download our Manufacturing Sales Handbook here.

Part of this blog post appeared in an article that was first published on the G2 blog

Deutsch

Deutsch