Engineer-to-order projects are intricate and elaborate. They involve extensive time and expertise in order to create a sales quotation. Manufacturers need to find methods to efficiently decrease the cost of execution, but still ensure that quotes are accurate and tailored correctly for tenders and projects. This is something that off-the-shelf Configure-Price-Quote (CPQ) solutions cannot manage; it requires a complete digital sales platform tailored for manufacturers.

Ability to Collaborate with Other Departments

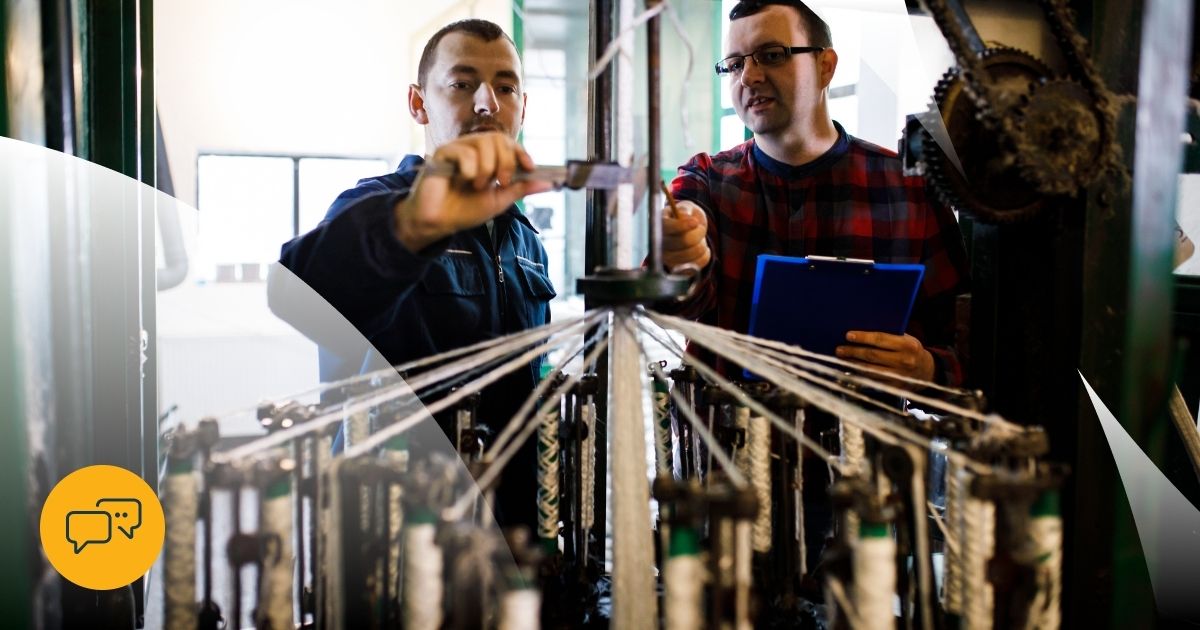

Sales engineers are used to communicating with multiple departments. After all, in order to offer an engineering solution, it is necessary to include the input of multiple departments. From product designers, to purchasing departments, to tender managers and production teams - sales engineers have to be the glue that coordinates the entire tender process. If they fail, the tender submission will be either inaccurate or delayed. Both of which will eventually erode margins and cause low customer satisfaction (which, as we have covered before, is not something to be desired).

However, seamless collaboration is not easy to configure. It requires automated routing that guarantees step-by-step input and interplay between departments. These trigger-based workflows will need to streamline internal processes, with approval notifications sent to ensure feasibility. To guarantee that managers and sales engineers alike can keep track of the tender status, a visual status overview is important. It needs to encompass different versions of the quote available to other parties.

In any manufacturing sales scenario, a penny-perfect quote is often the first step towards a successful transaction. To full understand how digital can improve the sales process, download our latest Manufacturing Sales Handbook!

Updated Production Data and Material Creation

Of course, this collaboration would not work without up-to-date data that can be used for the tender. One of the main features of an engineer-to-order tender is the massive amount of data that is necessary for creating an accurate quote. If that data is not updated and made available for the internal parties, it will result in inaccuracy or errors.

It means that a manufacturing sales platform should do three things:

- Centralize all required data in one easily accessible system

- Ensure data stays updated--from frontend to backend

- Make it always available to the relevant parties that need it

To do this, backend and production data from the ERP need to be integrated with your frontend for a complete digital sales platform. This establishes a single, accurate source of data that all internal parties can refer to. That will include pricing data which gets updated over time or over the product life cycle.

An ideal solution for engineering sales can estimate and simulate costs. But it should also be able to propagate that information into the ERP. This avoids double data creation, and helps streamline the quote-to-production cycle using accurate engineering data from start to finish.

A digital sales platform built for manufacturing businesses should also be able to automatically sync new BOMs or new data created within its solution into the backend ERP system.

Efficient Tender Composition

After the collaborative process is set up and the data is integrated, the last step in configuring a tender is the actual composition. When it comes to consolidating the requirements for the tender, there’s a need to include a variety of different documents and drawings, such as CADs, Excel sheets, raw data, and more. A manufacturing sales platform has to be able to handle different types of uploads and combine them in the most efficient way.

Modeling is crucial, and in addition to using accurate data, the modeling process has to be streamlined and maintained within the solution. The digital sales platform should also allow for the import of configuration Excels, Bills of Material (BOMs), and other documents to simplify the configuration and costing process.

A standout digital sales platform can store, embed and generate technical drawings such as CAD files within the project configuration. This feature can help reduce the amount of collaboration needed to make changes to a CAD drawing.

In the end, engineer-to-order companies have different requirements from other manufacturers. They would require a tailored solution that allows them to create a quotation as efficiently as possible. That includes features such as trigger-based workflows, tender composition tools, and tight integration to the back-end.

Transforming your manufacturing sales processes is a simple concept. However, implementing it could prove difficult without an understanding of how it works. Download our Manufacturing Sales Handbook to get a full overview of how your manufacturing business can sell better!

Deutsch

Deutsch