How our customers increase revenue by being easy to buy from

Contents

- Fluid handling manufacturing is under pressure to evolve

- The four key market challenges for fluid handling manufacturers

- The top seven sales hurdles in the fluid handling industry

- Configuration of complex products and solutions

- Calculating penny-perfect costs and prices for projects

- Incurring high cost-of-sales through engineering needs

- Sales organization siloes through divisions and channels

- Missed growth opportunities from upselling or cross-selling

- Market requests for leasing or rental options

- Collaboration gaps with customers

- Using customer-centricity to gain market share

- The digital fix for sales challenges of fluid handling manufacturers

- Configuration of complex products and solutions with CPQ and visual configuration

- Calculating penny-perfect quotes with advanced costing and pricing

- Reducing high cost-of-sales and facilitating collaboration with other departments or clients

- Leveraging growth opportunities with a CRM and Commerce

- Empowering agile business models

- A value-added sales scenario: How to create a fluid handling solution offer in one day

- How does digital sales for fluid handling manufacturers work?

- Conclusion

Fluid handling manufacturing is under pressure to evolve

The fluid handling industry caters to businesses from almost every sector. Its products range from the ubiquitous—pumps, pipes, valves, and storage tanks—to highly sophisticated measurement systems, sensors, and automation equipment powered by leading-edge IoT technology.

The four key market challenges for fluid handling manufacturers

The US$73 billion fluid handling system market is expected to maintain steady growth fuelled by increasing demand from various sectors including oil & gas and pharmaceutical. However, this demand comes with its own set of evolving expectations and challenges.

-

Increased Competition

Incumbents in the fluid handling manufacturing industry are facing stiff competition. They need to compete against one another globally while keeping up with local or niche start-ups, cheaper third-party component manufacturers, and B2B marketplaces. At the same time, manufacturers also need to adjust their business model to meet the demand for more flexible engagement models—such as equipment rental or consumption-based models—which disrupt the market.

-

Rising customer expectations

Customers are under pressure to improve performance, leading them to expect more value from their suppliers. They want their vendors to:

-

The growing pains of Industry 4.0

The manufacturing industry is undergoing digital transformation, and fluid handling manufacturers are no exception. As manufacturers digitalize production, the amount of data generated increases—but most manufacturers cannot extract value from this data due to data siloes.

-

Evolving consumption models

Even before the COVID-19 pandemic, businesses have been changing their buying behavior to lower costs. They want to rent instead of buy so that CAPEX is shifted to OPEX. This scenario has led to equipment-for-hire businesses springing up and manufacturers offering subscription models for aftersales services.

Opportunities are abundant in the fluid handling industry. But is your business equipped to capitalize on them? Find out in our upcoming webinar for fluid handling manufacturers. Sign up now!

The top seven sales hurdles in the fluid handling industry

Market pressure is mounting, and many equipment providers are starting to re-evaluate their existing business models or go-to-market strategies to cope. One of the key areas of focus is managing the complex sales process.

-

Configuration of complex products and solutions

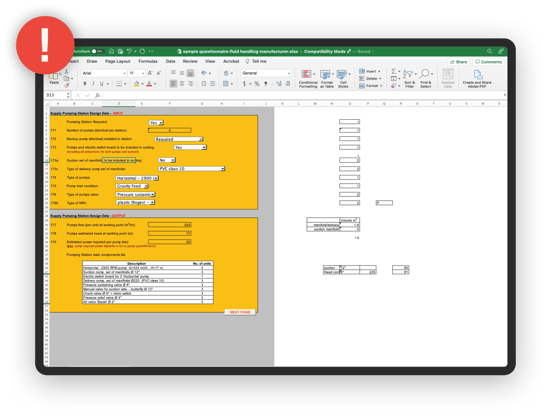

The traditional way of selling fluid handling systems involves a large variety of factors. Configuring a solution that matches the customer’s needs requires a deep understanding of the systems and extensive industry knowledge.

For example, choosing the right pump is highly dependent on the type of fluid & application. Customers typically need centrifugal pumps for residential & commercial water, dewatering & submersible wastewater applications, progressive cavity pumps for sludge or high-pressure applications, positive displacement for pumping high viscosity fluids, and diaphragm pumps for Industrial and mining wastewater applications.

Next, landscape considerations like nett positive suction head available (NPSHa) versus nett positive suction head required (NPSHr) in the selection process, involving complicated fluid mechanics calculations to determine best pump selections based on dynamic friction losses like fluid temp, application elevation, static losses and finally, add on valves, connectors, gauges, bends, pipes, meters, and sensors—each item with its own set of configurations—to complete the system.

Sales teams need to find the right balance between performance and price while setting aside some time for the odd case where an application requires special equipment configurations. That is only a surface-level overview of the sales process in the fluid handling manufacturing industry. In the background, there is a whole host of other factors that further complicate the sales process.

Example of manual costing and pricing via multiple Excel templates

-

Calculating penny-perfect costs and prices for projects

For project-based offers, costing and pricing, estimation are important steps in the sales process. They determine the final values that make—or break—deals. Sales reps need cost estimations to be as accurate as possible when they present the final offer to a customer, but getting them right is extremely difficult.

Dependencies between requirements and right-sized product combinations can be complicated. In project settings, sellers need to consider the local market environment and differentiated costs of components, which also change according to market conditions, and they need this data in real-time. Lead times and stock availability are important factors too.

If costs are increasing, sellers need to either reduce their margins or increase prices, which has a significant impact on the business. The final number and availability are only valid for a short period. The longer your customers prolong the deal, the more inaccurate pricing estimates become, and the more likely inaccuracy will affect your margins.

Spreadsheets are still used to store project data and perform calculations. However, scaling this process can become tedious and time-consuming. Data entry and calculations might have to be performed on tens or hundreds of lines and values each time a customer asks for a quote or changes their request.

Example of manual costing and pricing via multiple Excel templates

-

Incurring high cost-of-sales through engineering needs

Engineering knowledge is at the foundation of a fluid handling manufacturing company’s business. It is one of the core assets of the manufacturer but also one of its biggest cost centers. Engineers are engaged to develop and innovate on hundreds of different products like pumps, valves, and meters, whilst ensuring processes and systems are in place to fabricate products and solutions of the highest quality.

In the sales process, engineers also lend their knowledge and experience to ensure that proposed solutions are feasible, cost-effective, and above all, bring the expected value to the customer.

When the customer requests changes, it is the engineers’ job to modify the proposed systems to ensure they meet new requirements while keeping the solution sustainable

and profitable.However, each time engineering is involved, the costs increase, and the engagement slows down momentarily. Engineers in the sales process are an indirect overhead that is critical to a project’s success but can cause cost-of-sales to increase exponentially.

To reduce this cost, manufacturers can capture and digitalize the company’s engineering knowledge and expertise. It would then need to be made easily available and accessible to your sales team. To further reduce the cost of sales, manufacturers would need to define all applicable workflows of typical scenarios that let sales teams or even partners and distributors collaborate with engineering effectively.

Example of manual costing and pricing via multiple Excel templates

-

Sales organization siloes through divisions and channels

Fluid handling manufacturers now service the needs of customers all over the globe. As their reach grows, so does their sales network. Manufacturers depend on direct sales, local sales divisions or subsidiaries, partners, dealers, and distributors to ensure customers enjoy consistent service regardless of where they are.

The biggest hurdle for manufacturers is consistency. In an ideal situation, service quality remains the same whether the customer deals with the manufacturer directly or via a third party. However, for many manufacturers, the reality is quite different. Each sales channel operates differently—even within the same organization. Product divisions or regional sales teams may have unique workflows and processes, resembling partner or reseller operations.

Factors like currency exchange, knowledge transfer, calculations, discounts, and even culture all play a part in defining the final customer experience. To maintain a consistent customer experience, manufacturers must strategize on a sales structure that is smooth, easily replicated, and conveniently accessed by all stakeholders.

With such a structure in place, manufacturers can be well equipped to manage issues that hinder a perfect buying experience for customers. Sales channels will be able to work with consistent prices and collaborate better to find the best solutions for customers.

-

Missed growth opportunities from upselling or cross-selling

In fluid handling manufacturing sales, pumps are often in the spotlight. Sales reps focus on selling the manufacturer’s flagship products but can ignore the add-on products like sensors and meters. That’s because the add-on products can number in the hundreds and can be hard to keep track of, much less sell.

However, these oft-ignored smart products could represent significant growth potential for manufacturers that specialize in pumps for example. By automating prompts to upsell or cross-sell these products, manufacturers can uncover a path to increase revenue substantially.

Another benefit of cross-selling and upselling to existing customers is that it takes significantly less effort than finding new customers. The return-on-investment is much higher in the latter case. Manufacturers should note that cross-selling and upselling is not simply a case of adding on products your customer doesn’t need. It is about adding value for your customers.

By adding meters and sensors to a fluid handling system, you might be prolonging a pump’s lifespan, enhancing the quality of the system’s final product, or reducing maintenance costs—helping them solve problems in ways they may not have considered. By taking a customer-centric approach to business challenges, manufacturers can also add value to the relationship, leading to improved customer retention.

-

Market requests for leasing or rental options

For small and medium-sized customers, leasing equipment like pumps, mixers, or control stations can be a huge advantage for their business. Given this option, SMEs can free up a significant amount of capital to keep their cash flowing or divert it to some other business area.

This advantage is now fuelling demand for equipment rental or leasing. Besides renting from manufacturers, businesses can also choose from third-party equipment rental providers. This wide variety of choices puts pressure on incumbents to offer the same rental or leasing options to their customers.

While this situation can be a challenge, smart manufacturers can use it to their advantage. Unlike third-party rental providers, manufacturers can offer customers access to more equipment and tools and have the matching expertise, spare parts, and consumables.

Customers can also upgrade to the latest pumps and sensors. By eliminating large initial investments for the customers, rental or leasing options become attractive enough to secure a deal. Manufacturers can retain margins without having to use any margin-eroding discounts.

When the deal becomes a palatable monthly sum, manufacturers can confidently upsell pumps with better specifications and add-on products like smart meters and sensors according to the customers’ needs rather than their budget.

However, fluid handling manufacturers are already dealing with a highly complex sales model. Adopting a new business model to complement the existing ones can require new and even more complex calculations to get the prices and margins right.

-

Collaboration gaps with customers

One of the biggest challenges is collaboration with the customer—or the lack thereof. For the past few decades, sales in the fluid handling vertical have been highly dependent on expertise on the client-side and the manufacturer side. Your clients need to know their problem, and your sales teams need to know how to solve it. Finding the right solution requires close collaboration between the two.

Finding the exact solution that fits to take the deal forward can take weeks or even months. Firstly, clients would have to prepare a precise description of their problems in a requirements list.

Next, your sales teams would take these requirements and manually figure a feasible solution from a catalog full of different pumps, systems, sensors, and controllers.The above step alone needs seamless communications and collaboration with several departments, each with its own set of technical or engineering knowledge from employees or external systems. After all that work, comes the manual calculation of prices and quote generation. Along the way, errors, inconsistencies, or disagreements can take sales back to square one.

A large number of administrative activities can put a heavy strain on your sales team. They would spend more time on the sales process instead of focusing on what they do best: selling.

Are you looking to build a case for investing in digital sales? Download this article as ebook for offline reading here.

Using customer-centricity to gain market share

Many leading manufacturers recognize the problems of manual sales management and are turning towards digital technology to close this gap. Add customer-centricity—and you have a proven strategy for manufacturing firms. They are constantly asking questions like:

-

“How can we make it easier for our customers to buy?”

-

“What are the channels our customers prefer to use?”

-

“How can we meet them where they are?”

By putting yourself in your customers’ shoes, you will be able to create a smooth journey that helps customers buy easily and helps your business sell quickly.

The digital fix for sales challenges of fluid handling manufacturers

-

Configuration of complex products and solutions with CPQ and visual configuration

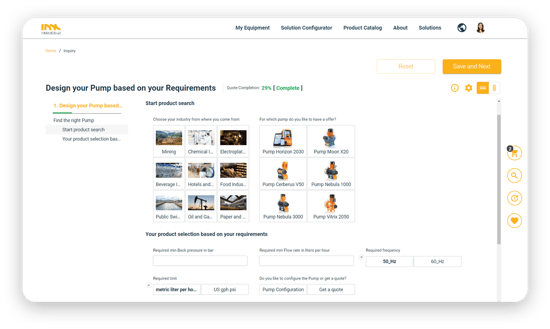

Example of In Mind Cloud configuration through visual product finder

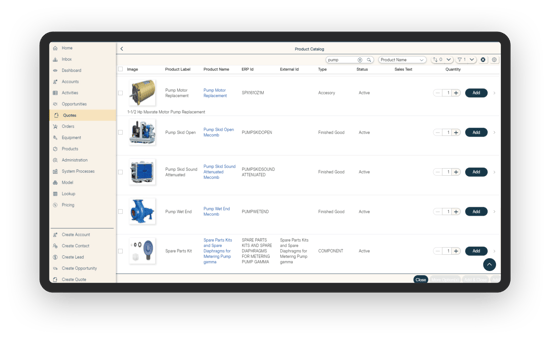

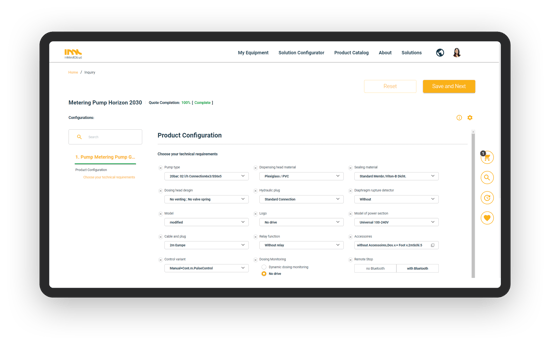

At the most basic level, a Digital Sales Platform helps manufacturers streamline the configuration process. It turns your engineering and product knowledge into data, which is made readily accessible by the configuration system.

Configuring a full system, whether for irrigation or food processing, is now done by selecting requirements, leading to a technical proposal. To start, customers or sales reps only need to input all the parameters like pressures and fluid type, and the system will generate a list of products or systems that correspond with the parameters.

Digital Sales Platforms such as In Mind Cloud also come with advanced tools like Google Maps integration. This is helpful for free field projects which relate to topography. In the case of one of our customers, a leader in smart irrigation, the sales rep locates a field in Google Maps.

With a few clicks, the system calculates the hydraulics, press, pipe diameters and recommends the right pumps, filters, and all other equipment needed to irrigate the field.

Other types of technology include 3D visualization used in configuration. Manufacturers can re-create complex equipment like pumps or turbines digitally. This feature allows the sales rep or customer to quickly understand the product specifics or select the right spare parts needed for repairs or maintenance.

The most obvious advantage for manufacturers is speed. However, precision also plays a large role. In most cases, a system-generated solution can be more than 95% accurate compared to a skilled engineer with respect to price precision. A precise solution generated quickly (in minutes instead of days) leads to better productivity, lower costs, and higher return on investment.

With a digital sales platform in place, manufacturers can quickly offer 100% turnkey solutions that include subsystems and components like valves, filtration, or irrigation.

-

Calculating penny-perfect quotes with advanced costing and pricing

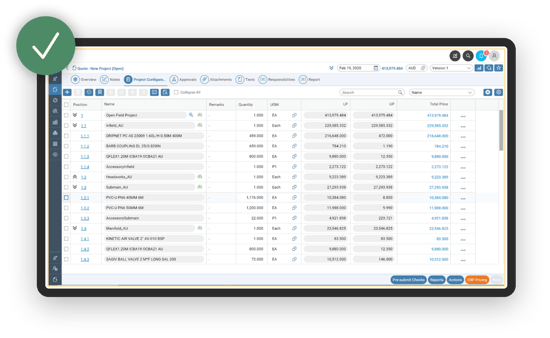

Example of In Mind Cloud costing and pricing

In the fluid handling vertical, manufacturers often have a large variety of products, add-ons, and solutions. Multiply them by the number of industries your business works with, and you get a nearly infinite number of solution combinations.

With a digital sales platform, the product, solution, and engineering knowledge data are made readily accessible across all your sales channels. It can organize data like prices and present it according to the party accessing it.

For example, in your sales portal, internal sales staff would be looking at one global price (with ERP-maintained FX rates, regional discounts, or mark-ups applied), while suppliers, distributors, or clients would be looking at prices tailored to them.

The key feature in modern sales platforms is powerful, split-second calculations. This function can be applied to every sales calculation like price simulations, discount calculations, change management, or even cost fluctuation. The goal here is to ensure margins are always secure.

Here’s an example. In water management, your customer requires a system that includes water monitoring instruments, sensors, process control systems, pumps, pipes, and valves.

With a digital sales platform, even an inexperienced sales rep or partner can simply select the requested items via the online configurator. The system automatically generates a price for the solution instantly.

In the background, the system performs the calculation using real-time ERP data like costs, prices, currency exchange rate, add-on service rates, and account-specific discounts.

The result? A 100% accurate quote in minutes.

Experienced sales reps can even perform price simulations using an interactive costing and pricing feature to compare profit margins of different configurations. In doing so, they can generate best-fit solutions for the customer, increasing the chances of sealing the deal.

Reps can add more equipment like piping or higher-end pumps to see how they can stay within budget yet provide the customer with a better performing system. For manufacturers, this feature is an invaluable opportunity to not only upsell (or cross-sell) but to add value as well.

-

Reducing high cost-of-sales and facilitating collaboration with other departments or clients

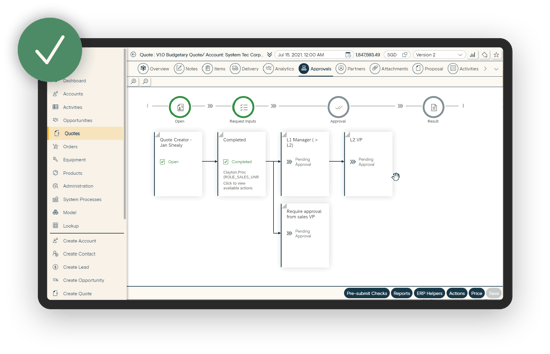

Example of In Mind Cloud collaboration through workflow routing and approval automation

In the fluid management vertical, cost-of-sales is a key factor that can affect profits. The more it costs the manufacturer to sell, the slimmer the profits become. For manufacturers, lowering the rising cost of sales is only logical.

However, the bulk of the cost-of-sales comes from person-hours. Sales teams—which include expensive sales engineers—spend most of their time on administration and only a third of their time selling.

With a Digital Sales Platform, this statistic could potentially be reversed. Much of the tedious routine work can be automated. The key here is to digitize your manufacturing firm’s precious knowledge and make it readily available throughout the organization.

For example, it takes an experienced sales engineer ten seconds to remember which pump the customer needs to move gravy from one end of the plant to another. But it also takes them days to configure a system for the customer’s new plant, align and calculate the prices, fix errors, get approvals, adjusting for exchange rates, calculate discounts, and send the final quote.

A powerful Digital Sales Platform gets those steps done in minutes. The sales engineer inputs the parameters according to the customers’ requirements, and the system generates a highly accurate solution.

The sales engineer might also decide to adjust the relevant values based on experience and customer requirements. The system quickly generates a quote that can be approved, returned, and sent to the customer on the same day.

This scenario is only possible with automated approval workflows and gateways within the system that makes cross-department collaboration fast, seamless, and effortless.

As the saying goes, time is money. And in the business of pumps, valves, meters, sensors controls, and more, your sales teams would be able to spend their time on securing new customers or adding value to existing accounts.

In other words, sales automation does not reduce the value of sales work. Instead, it enhances the abilities of sales teams, enabling them to become more productive and cost-effective.

-

Leveraging growth opportunities with a CRM and Commerce

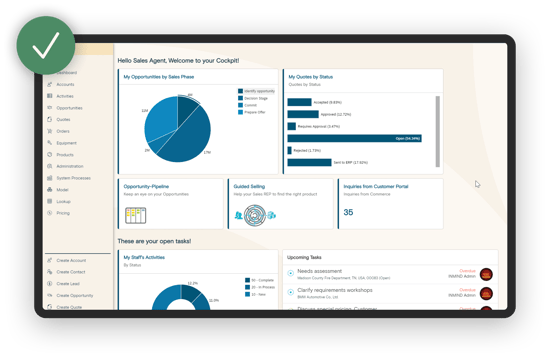

Example of In Mind Cloud Sales Cockpit to prioritize opportunities

Intelligent sales automation also solves the issue of missed growth opportunities. This is where the CRM function of a Digital Sales Platform comes in. However, many manufacturers today are pressured into force-fitting a standard CRM to fit their needs.

A standard CRM from a leading vendor is great at what it was built for: contact management, activity tracking, and opportunity management. But for fluid management system manufacturers, it leaves a huge gap between the manufacturing process and the customer.

A Digital Sales Platform built for the industry bridges that gap by aligning your customer wishes with your production capabilities and ERP—the system that holds your costs, prices, variants, account discounts, shipping costs, taxes, stock availabilities, and delivery times.

When your sales platform is connected to the ERP, your sales channels (sales reps, partners, e-commerce, etc.) use the latest, most accurate data to sell. This process is automated and can eliminate the manual extraction of data, freeing sales reps from administrative tasks to focus on selling.

At the same time, your business gets a complete overview of your customers. With Customer 360, you can see what customers buy, how much they paid, and what channels they used—all from a single dashboard. You stay in control of how their buying journey unfolds and align it with your business’s capabilities.

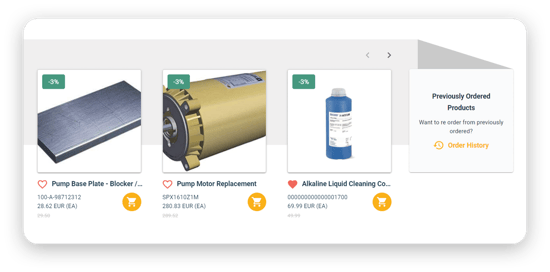

Through the comprehensive dashboard, you can also quickly spot opportunities to upsell and cross-sell instantly. But the most powerful feature of a digital sales platform is its ability to automate the upselling and cross-selling process by suggesting spare parts, consumables, or follow-up products based on the customer’s install base.

Instead of showing them thousands of pages of products and specs and expecting a customer to choose, the system tells them exactly the type of valve which goes with their pump or the consumables that they may run out of soon.

This approach improves the user experience and increases the chances of your customers staying with you for aftersales products, while also keeping your backend systems updated. Your ERP maintains base product data, while your Digital Sales Platform handles the frontend essentials like configuration.

A powerful digital sales platform also lets your customers buy on their terms. It offers transparency on pricing and delivery. When your customer gets the best possible buying experience, they also get peace of mind—which means they aren’t likely to turn to your competitors anytime soon.

-

Empowering Agile Business Models

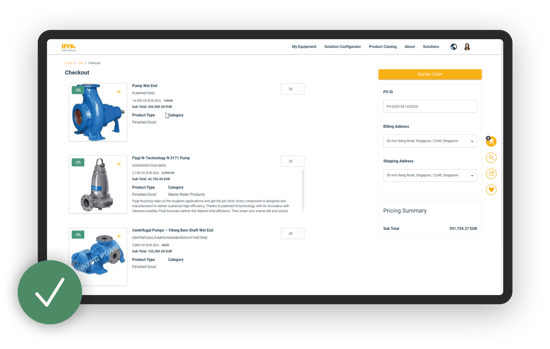

Example of In Mind Cloud Online Sales Portal

Pressure is starting to build in the fluid handling vertical. Customers are changing the way they operate. As mentioned above, many now have a preference for renting large format equipment like pumps or entire fluid management systems.

A leasing approach helps customers keep their cash flowing, but it can cause more trouble for unprepared manufacturers than the usual one-off asset sale.However, leasing and rental can easily become a predictable, recurring revenue stream. Instead of ending a transaction with an asset sale, manufacturers can offer additional services such as maintenance, safety analysis, or performance tracking through subscription models.

It can also give the manufacturer complete control over maintenance, rather than leaving it to third-party businesses—enabling them to extend the service life of equipment, systems, or stations.

Research also shows that agile companies outperform the competition when adapting to shifting business landscapes. They offer customers what they want, how they want it—instead of pushing products and forcing customers to conform. Your customers have more than enough options in the market not to play along.

Fluid management system manufacturers that make subscription models work rely on digital solutions to do so. For example, in sales, there are standard digital tools that manufacturers use to track sales performance. The data collected can give sales leaders an idea of how well they are selling and which opportunities they should pay attention to.

A digital sales platform, on the other hand, can offer much more value. It can provide access to sales-critical data in the ERP, which it organizes and makes instantly available to every part of the business. Not just sales. This allows the relevant business units to collaborate seamlessly and create a perfect pricing strategy that is feasible for both the business and the customer.

And finally, a Digital Sales Platform also has e-commerce functionality, the final piece of the puzzle of an end-to-end customer buying experience. Customers, distributors, or partners can easily log on to a sales portal, configure, order, and subscribe to the systems and solutions they need—often in minutes.

A value-added sales scenario: How to create a fluid handling solution offer in one day

To manage sales, fluid handling manufacturers used to rely on several technologies—which often require extensive integration to work together. But today, fully integrated solutions can provide a manufacturer with the seamless end-to-end sales platform they need.

Such turnkey solutions deliver features and functions that enable more efficient selling of systems, or equipment right out of the box. Here’s a quick example of how a digitalized sales process can make it easier for customers to buy a fluid handling system.

-

The customer needs help with pumps for an irrigation project.

-

They go to the online portal to find a suitable solution.

Example of In Mind Cloud Online Portal login

-

The Guided Selling process will lead the customer to a selection of viable products based on their requirements.

Example of In Mind Cloud Guided Selling for pumps

-

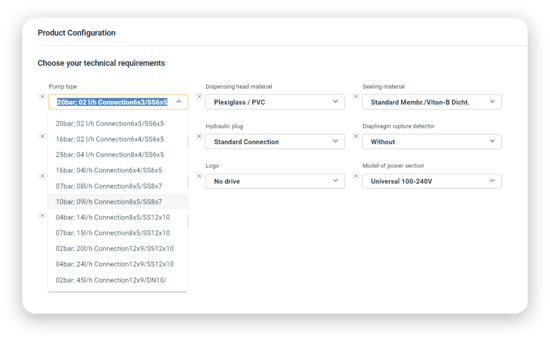

The customer selects the desired pump type and adjusts some parameters to configure their optimal solution.

Example of In Mind Cloud configuration detail amendment

-

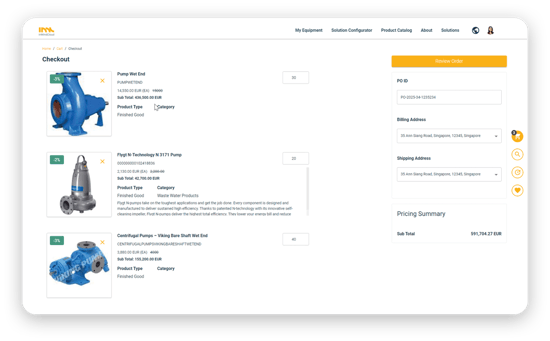

Once the customer is done, the system recommends additional products that complement that configured system.

-

The system generates an accurate quote with all requirements incorporated and all costing calculation is done through real-time ERP access in the background.

-

A pre-determined account discount is applied automatically.

In Mind Cloud example of smart discounting in shopping cart

-

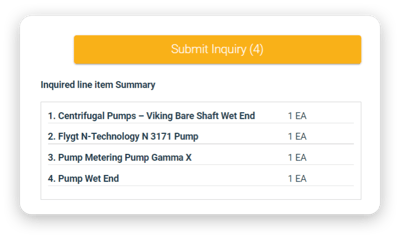

The customer decides to submit the inquiry, which is then received by the manufacturer’s sales team.

In Mind Cloud example of Inquiry function in Online Portal

-

The customer will now receive a phone call from a sales rep who has the best experience for this kind of customer challenge.

-

The sales rep works with the customer to confirm the selection or refine the solution for the specific challenges.

-

Once the customer is ready to buy, the sales rep can trigger the order in the ERP system with one click.

-

If the customer chooses to lease, the sales rep can add on services that help the customer maintain their system over the duration of the lease.

-

Once the initial transaction ends, the sales rep guides the customer to the manufacturer’s spare parts portal, where they have 24/7 access to spare parts, upgrades, or consumables matching the purchased equipment.

Example of In Mind Cloud recommended products in Online Portal

A Digital Sales Platform can streamline the entire buying process in your fluid handling business

The buying process described above doesn’t need to take more than a day. This is sales efficiency at its best.

How does digital sales for fluid handling manufacturers work?

In the simplest of terms, sales digitalization takes all your engineering expertise, costs, pricing, and product information from your ERP, and makes it consistently available to your sales reps, subsidiaries, partners, dealers and distributors, and your customers themselves—24/7, in real-time, and from anywhere in the world.

Example of In Mind Cloud Product Catalog in Online Portal

Instead of having your customer search for information, a Digital Sales Platform neatly organizes and presents the information your customer needs in order to buy. It also guides the customer along the sales process until they are ready to engage with your sales reps.

Example of In Mind Cloud 100% complete configuration

In other words, it makes your complex products and solutions simple to buy.

With a Digital Sales Platform, fluid handling manufacturers get:

|

|

|

Conclusion

Selling fluid handling systems and technology can be highly complex. At the same time, it is the driving force that increases the ROI of sales automation and digitalization. The more complex the sales process is, the more your business gains from digitalizing it.

Manufacturing companies are ready for digitalization. The data in your ERP and your engineering expertise are your biggest advantages.

All that’s left is a powerful manufacturing sales platform that can give your sales teams and customers access to this data and the engineering tools they need to craft the best-fit fluid handling system.

With a unified Digital Sales Platform, manufacturers can easily manage the complexity of engineering challenges, costing, configuration, and global pricing. It can also enable new sales channels out of the box, so manufacturers can keep up with global demands and improve competitiveness.

Deutsch

Deutsch