What is make-to-order (MTO) manufacturing about?

In MTO businesses, standard products with clearly defined specifications are manufactured and sold when orders are received. In this model, inventories are easily managed, and the risk of overproducing is eliminated as market demands are clear. But in today’s consumerized B2B world, customers are increasingly becoming impatient. They don’t want to wait for their products to be produced.

Also, the “economies of scale” concept in mass production is rarely applicable for the MTO model. Manufacturers cannot guarantee a steady stream of orders, so production costs and prices are likely higher due to low quantities. Plus, manufacturers in MTO cannot plan the ideal utilization of a production line and schedule. All too often, this results in accepting low-margin orders to utilize the line.

In recent years, however, Industry 4.0 technologies such as additive manufacturing (3D printing) are helping MTO businesses produce goods in lower quantities at lower costs. The industry term is “lot size of one,” where an MTO business can produce a single product at the lowest possible cost. Demand for customization in MTO is also on the rise. However, it is incredibly complex to sell. Cost calculations need to be immaculate for MTO businesses to achieve profitability.

Download our Manufacturing Sales Handbook to find out more about the MTO model and how digital can help accelerate sales for businesses using this model.

Risks that affect MTO model sales strategies

Besides changes, MTO manufacturers must manage factors that affect delivery time

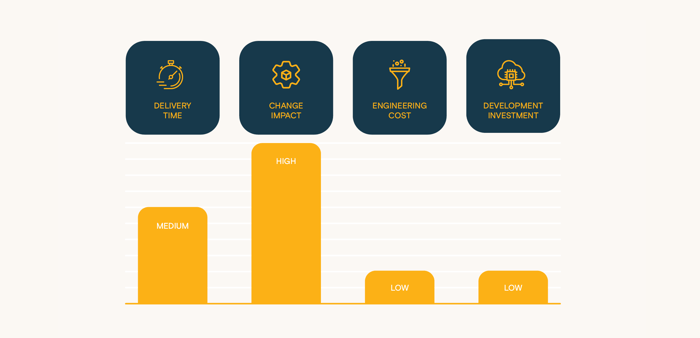

The chart above outlines the four key risks that all manufacturing businesses have to consider during operations. Each model handles risk differently. Some models can bypass certain risks by transferring the risks to other areas of the business. In the following segment, we highlight the primary risks of the MTO model and how it can affect their sales.

Risk 1: Time needed to deliver products

The make-to-order model is similar to the make-to-stock model we covered before. The only difference here is that MTO manufacturers wait for orders to come in before producing the goods or products. This eliminates the risk of over or under production, but it also increases the customers’ waiting time for the products they need.

Risk 2: Agility and the impact of change

Like MTS manufacturers, MTO manufacturers are vulnerable to change. Their production lines are calibrated and tuned to a particular design. This is done so once orders come in, they can start manufacturing right away. Any changes to the product’s design could result in the manufacturer spending more on engineering or design and adjusting the line to accommodate the changes.

Risk 3: Cost of engineering incurred and risk of design error

In the MTO model, investment into manufacturing infrastructure is made at the beginning. When the production line is running, no further development is necessary. Manufacturers can focus on operations and innovating on the next product they want to offer customers.

Risk 4: Investment needed in development

In the MTS model, investment in building a manufacturing infrastructure is made at the start. Once the business is up and running, manufacturers rarely need to spend more on further development. This enables manufacturers to focus on innovation and keep the costs of production low.

How an MTO manufacturing business can improve sales

An MTO business is similar to that of an MTS business. The difference here is that goods are produced only when the manufacturer receives an order. This helps keep inventory levels manageable and production lean. On the other hand, the MTO model loses the advantage of fast fulfillment, unlike MTS businesses. Their customers have to wait longer for the products or goods they need.

Manufacturers using this model also need to deal with higher production costs—more so if the customer requires customization. Their production facilities are built with limited production numbers in mind. Since economies of scale are not applicable to their products, it makes the MTO business model right for high-value products that are prohibitively expensive to keep inventory for. The MTO model is often used for products like servers, vehicles, or large equipment.

For manufacturing businesses using the MTO model, a fully integrated digital sales solution could prove to be indispensable. Especially for the MTO manufacturers that accept low-margin orders to ensure that their production line is being utilized. A Digital Sales Platform performs constant calculations of costs and prices based on ERP data to ensure that the manufacturer never quotes using loss-making prices.

A modern digital sales solution can also help manufacturers offer more configuration options to their customers. Its direct integration with the ERP ensures that orders and their unique configurations are fed directly to the production lines to ensure 100% accuracy—a complete alignment between business and customer. With a digital sales solution, manufacturers can also take their entire business online. Through a custom sales portal, manufacturers can empower customers with the convenience of making orders and configurations on their own.

This powerful self-serve feature helps customers achieve their goals fast and keeps them coming back for the same excellent buying experience for their aftersales needs. It also takes the burden of preserving margins or smaller deals off the sales team, allowing them to pursue and close much bigger deals that require more attention, and expertise.

These capabilities can also be extended to the manufacturer’s third-party sales network. Through a digital sales platform, your partners, dealers, and distributors can simply log in to the system and get controlled access to the manufacturer’s business. This access helps them provide the same excellent buying experience to their customers.

Explore how the In Mind Cloud Digital Sales Platform can transform the way your business sells. Download the Manufacturing Sales Handbook to find out how our Digital Sales Platform is ready to elevate your manufacturing sales. If you have further questions, you can always book a no-obligation consultation with our manufacturing sales experts to get your answers.

Deutsch

Deutsch