What is make-to-assemble / assemble-to-order manufacturing about?

Make-to-assemble or assemble-to-order is a hybrid between make-to-stock and make-to-order. The manufacturer will produce components or parts in anticipation of orders for assembly. He will decide at which position in the Bill of Material (BOM) the material is kept in stock readily available for processing.

While the manufacturer is ready to fulfill customer orders instantly, he can also be left with unwanted parts or components when demand is low. Availability checks and lead times for these components need to be carefully considered. In general, ATO gives some flexibility, allows for speed in fulfilling market demands, and helps reduce waste, which leads to a lean and agile production model.

Download our Manufacturing Sales Handbook to find out more about the MTA / ATO model and how digital can help accelerate sales for businesses using this model.

Risks that affect ATO model sales strategies

The MTA/ATO model allows manufacturers to deliver faster while reducing waste

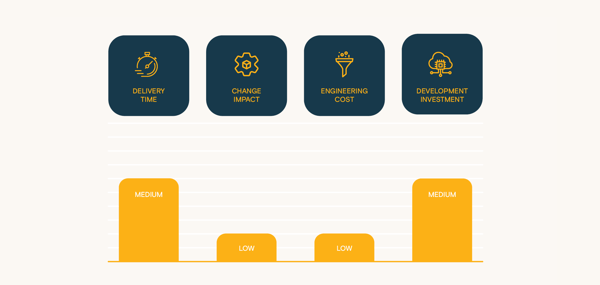

The chart above outlines the four key risks that all manufacturing businesses have to consider during operations. Each model handles risk differently. Some models can bypass certain risks by transferring the risks to other areas of the business. In the following segment, we highlight the primary risks of the MTA/ATO model and how it can affect their sales.

Risk 1: Time needed to deliver products

The MTA model is at the halfway point between the MTS and MTO models. Here, manufacturers produce parts of the products that sit in storage. Once an order comes in, the final product gets assembled and delivered. Waiting time for customers is slower than MTS and slightly faster than MTO models due to the time needed for the assembly of the products.

Risk 2: Agility and the impact of change

This model gives manufacturers the agility needed to react quickly. Changes to the final product are all implemented before the goods reach the final assembly line. For example, changes to a turbine’s rotor blade design can be made without major disruption to the business. Design changes can be applied when the blades are being manufactured, and will not affect final assembly.

Risk 3: Cost of engineering incurred and risk of design error

Like the MTS and MTO models, engineering costs are incurred at the design phase or at the start of the entire production process of a product. Any errors or flaws in product design can be rectified before the customer makes the orders or when the final assembly begins.

Risk 4: Investment needed in development

Investment into the manufacturing infrastructure for MTA businesses can be higher than MTO or MTS businesses. An MTA would need to build infrastructure to manufacture individual parts of the final product, and at the same time, build infrastructure for final assembly. However, during the production phase, minimal resources are required for further development.

How an MTA manufacturing business can improve sales

The MTA strategy includes elements found in the MTS or MTO models. In the MTA model, manufacturers would need to produce individual components and stock them. That makes demand forecasting instrumental in the business’s success. MTA manufacturers, in general, are susceptible to over and under-production—both of which could negatively impact their businesses. It is also not as agile or flexible as the MTO model, as production of components or parts begins before orders are received. However, unlike the MTS model, MTA manufacturers can store unassembled components until a customer makes an order.

While this approach gives MTA manufacturers more flexibility than MTS manufacturers, they also share some of the same risks. Accurate forecasting enabled by digital sales solutions is a crucial element in an MTA manufacturer’s success. It helps them anticipate the right amount needed to meet demand, and at the same time, avoid underproduction. It does this by capturing customer and sales data via an embedded CRM, which can be used to analyze the ups and downs of demand, and strategize production accordingly.

Another major benefit of a sales platform is that it also streamlines the MTA sales process. Manual work like price management and quote generation becomes semi-automated. The same technology working alongside an integrated eCommerce portal can help manufacturers offer customization options directly to the customer. Through an end-to-end digital sales solution, customers build best-fit solutions on their own and get precise prices before even speaking to a sales rep. Through automated margin protection, sales reps can then sweeten the deal with discounts that never eat into a manufacturer’s margins.

In summary, a robust Digital Sales Platform can digitalize an MTA manufacturer’s entire sales process. Customers and partners can simply log in, configure what they need using personalized rates, and buy at their preferred pace. On the manufacturer’s end, sales data is neatly captured and can be used to make informed business decisions. For MTA manufacturers, a Digital Sales Platform can be a game-changer and competitive advantage. It not only makes sales more efficient, but it can also help manufacturers explore new possibilities—new ways to sell and improve revenue.

Find out more about how the In Mind Cloud Digital Sales Platform can transform the way your B2B manufacturing business sells. Download the Manufacturing Sales Handbook to find out how our Digital Sales Platform is ready to elevate your manufacturing sales. If you have further questions, you can always book a no-obligation consultation with our manufacturing sales experts to get your answers.

Deutsch

Deutsch