What is configure-to-order manufacturing about?

Configure-to-order is a hybrid of make-to-stock and make-to-order. In CTO manufacturing, products are assembled and configured according to customer requirements. The standard subassemblies are made-to-stock and must be immediately available at a well-forecasted inventory level to quickly fulfill customer orders. The final assembly is postponed until the order comes in, which helps manufacturers remain flexible enough to offer high product variety.

Just as in MTO, this model helps manufacturers cope in today's competitive markets where tailored products with unique requirements are in high demand. The CTO system enables both mass customization and fast response time in order fulfillment. In CTO manufacturing sales, the complexity lies in the configuration. End-product standards are predefined but must be flexible enough to allow viable configuration.

Some manufacturers will define a material master record number for each variation of the standard product, or they use variant configuration models.

Download our Manufacturing Sales Handbook to find out more about the CTO model and how digital can help accelerate sales for businesses using this model.

Risks that affect CTO model sales strategies

The CTO model is highly agile but requires significant investment in making products configurable

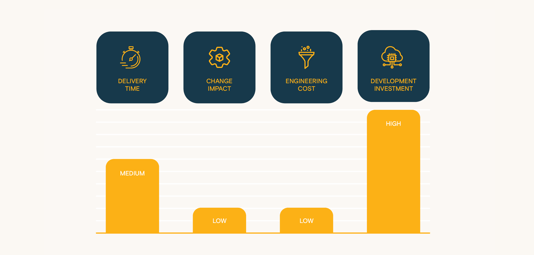

The chart above outlines the four key risks that all manufacturing businesses have to consider during operations. Each model handles risk differently. Some models can bypass certain risks by transferring the risks to other areas of the business. In the following segment, we highlight the primary risks of the CTO model and how it can affect their sales.

Risk 1: Time needed to deliver products

Manufacturers use the CTO model to offer unique products that match customer use cases. But due to the extra but necessary configuration step, assembly only happens after customers configure and place their orders. This tradeoff causes delivery time to be slightly longer than MTA or MTO manufacturing models. But in return, customers get the best-fit products or solutions for their business.

Risk 2: Agility and the impact of change

The ability to configure before production gives manufacturers a high degree of flexibility. Manufacturers can strategize their changes around the configurable parts without disrupting the production of the entire product.

Risk 3: Cost of engineering incurred and risk of design error

Like MTS, MTA, and MTO manufacturers, CTO manufacturers are not hindered by high engineering costs or design errors. Since engineering and design are also done initially, flaws and errors can be ironed out before the manufacturer even offers their configurable product for sale. If some errors or flaws are found, manufacturers have the flexibility to rectify only the affected configurable parts instead of the entire product.

Risk 4: Investment needed in development

For the CTO model, the risk is highest when it comes to investment in development. During the development of a product, manufacturers would need to spend more on design and engineering to ensure that their product is configurable. Like in the MTA model, CTO manufacturers would also need to invest in infrastructure to manufacture individual parts and final assembly.

How a configure-to-order manufacturing business can improve sales

The configure-to-order model gives manufacturers the flexibility needed to deliver configurable products that fit their customers' unique needs. However, they are also susceptible to the traditional risks that other manufacturers face. CTO manufacturers, like MTS manufacturers, depend on accurate forecasting to determine production numbers. However, CTO manufacturers need a higher degree of precision since a single configurable product can have many different types of the same components. For example, configurable healthcare furniture, like a surgical table, allows for various types of headrests and add-ons.

A manufacturer using the CTO model would need to accurately determine the number of headrests of each type. Having historical data of past orders can help manufacturers identify the most common types of headrests (so they can produce more, charge less) versus the specialized type (so they can produce less, charge more). Adding to this challenge is that CTO manufacturers offer configuration for more than just one product. When you multiply the need for accurate forecasting with all the configurable products (tens to hundreds) offered, you get an immensely complex sales situation—one that spreadsheets are ill-equipped to handle.

In the past, CTO manufacturers can only offer configuration of just a few products. And even then, the options available are highly limited. However, with Industry 4.0 era digital solutions like CPQ, configuration of products has become the norm. Customers are now demanding configuration, even for low minimum order quantities (MOQ). In addition, customers are spoiled by the dazzling array of configuration options available on consumer products. And they demand the same flexibility from their suppliers.

A Digital Sales Platform helps CTO manufacturers leapfrog this predicament entirely. It is a complete digital transformation of a manufacturer’s sales process in a single, cloud-based package. Its biggest advantage is tight integration with a manufacturer’s ERP—the brains of the entire business. This allows the Digital Sales Platform to access sales-relevant data directly from the ERP, and flow order data back into the system.

Here's a quick illustration of how a Digital Sales Platform—with an embedded CPQ, CRM, and eCommerce portal—works for a CTO business. It keeps track of product prices, costs, and inventory levels, and makes it available via product configuration in an online store. It then tracks customer and sales data which helps with decision-making. It comprises three separate functions—usually delivered by three essential but isolated software—and seamlessly weaves it into an end-to-end sales solution. The factor that seals the deal? It’s priced as a single solution.

But of course, a Digital Sales Platform is much more complex than what we just described. It also has smart features that intelligently automate manual tasks for CTO manufacturers. It can also help sales teams become much more efficient and ready to hunt bigger more strategic deals. Powerful APIs also allow manufacturers to add advanced tools like 2D/3D visualization, or map configuration that take customer experience to the next level.

Find out more about how the In Mind Cloud Digital Sales Platform can transform the way your B2B manufacturing business sells. Download the Manufacturing Sales Handbook to find out how our Digital Sales Platform is ready to elevate your manufacturing sales. If you have further questions, you can always book a no-obligation consultation with our manufacturing sales experts to get your answers.

Deutsch

Deutsch