The sales organization in your manufacturing business has always been a profit center. But the lines become blurred when it comes to the technology your sales team uses. Some manufacturers categorize it as an IT cost, but technology that improves sales should really be seen as a profit center.

Digitizing sales improves how your manufacturing business sells

Sales digitization with a customer-centric approach is your competitive advantage. It makes it easy for customers to buy, and for your business to sell. Manufacturers that take this approach report higher win rates of their offers by 20 percent to 40 percent. This improvement alone already pays for the digitization of your sales process—and the list doesn’t stop there. Costs of serving your customers can even be lowered by up to 50 percent.

These improvements are especially important now that manufacturers’ challenges are intensifying. Global competition is heating up. Customers are demanding speed, convenience, and self-service buying. The consumerization of B2B is accelerating. These are challenges that a customer-centric approach to digitization of the sales process can directly address.

Through an approach that prioritizes the customer’s buying experience, manufacturers will be able to find a more suitable digital transformation strategy for their sales process. The end result of such a transformation: Customers get an easier way to buy, and are more likely to return—a direct path to recurring revenue.

Manufacturers focus on transforming sales with digital to improve revenue generation. However, many of our customers report significant cost reductions as well.

Find out how digitizing sales can help lower costs across the board in your manufacturing business. Book a no-obligation demo with us today to find out how we can help!

Reduce costs through accurate costing and margin protection

Manufacturing is a high volume, low margin business. Businesses in this sector must ensure that their margins are healthy—or they can quickly face destructive losses. In this case, price management is especially important. In manufacturing, the price of a complex product can be affected by a large variety of cost factors. For instance, the price of a $30 snow shovel can be determined by costs of steel, tooling, wood, assembly, logistics, variable and fixed overheads, labor, and administration.

These costs are not just fluctuating, they are rising globally. Elevated inflation, supply chain disruption, logistics, and energy crises are compounding the problem for manufacturers—and they need a better way to stay on top of rising costs and shrinking margins to remain competitive and profitable.

For manufacturers of much more complex products, like an excavator, for example, their cost factors increase by several folds compared to a shovel. Keeping track of these costs manually through spreadsheets is slow, tedious, and just plain inaccurate. To overcome this challenge, industry leaders are increasingly turning to advanced solutions like CPQ software to manage a vast number of changing cost factors.

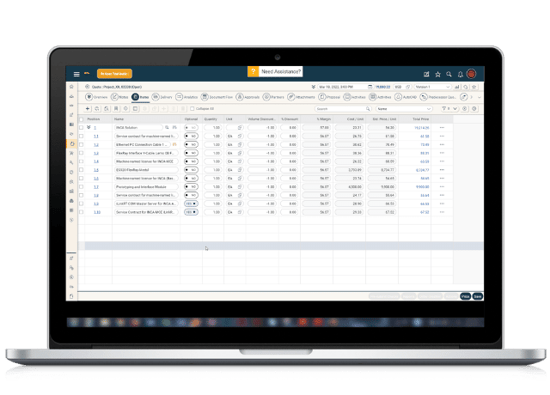

Intuitive costing and pricing management helps keep margins under control and healthy

The CPQ software or tool used is more often than not, integrated with the manufacturer’s ERP. This way, it is always updated with the latest costs, and even exchange rates. Some providers may have proprietary algorithms that can constantly calculate and adjust prices so that margins are always healthy. This process can be further streamlined if it is implemented by an experienced service provider that has extensive experience in the manufacturing industry.

Having a deep understanding of how manufacturers sell allows the provider to quickly create costing and pricing models from similar businesses or industry best-practice templates. The manufacturer then gives additional input to fine-tune the models so that the prices generated by the system are 100% accurate and always profitable.

When a CPQ provider works closely with manufacturers, they also gain insights into their sales workflows. This helps them design effective sales automation that can be further improved to match a manufacturer’s unique requirements. At the same time, checks and balances--based on industry best practices--are embedded into the workflows or sales process to prevent rogue or excessive discounts that impact margins negatively.

Reduce costs through digitization of knowledge, sales automation

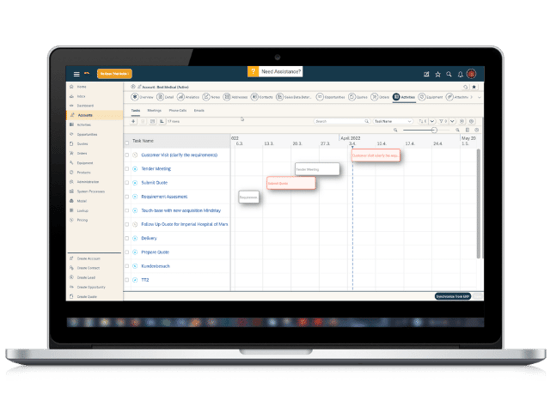

A large part of the costs in a manufacturer’s sales process comes from human resources. Besides sales reps, sales engineers and sales operations are also involved. Sales engineers are required to design solutions, while sales operations provide support (e.g. keep prices in check). Responding to an RFP or RFQ involves intense collaboration between all stakeholders. Once the quote has been prepared, it needs to go through the relevant parties for complete alignment.

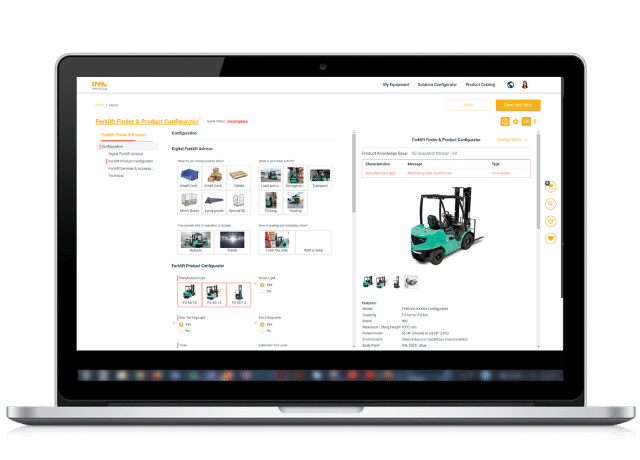

A manufacturing-focused Digital Sales Platform optimizes this process with automation and the digitization of knowledge. For instance, engineering knowledge on a product is captured and turned into a series of dropdown menu options. Configuring a product or solution to match requirements becomes as simple as selecting available options instead of a long back and forth between sales reps and sales engineers.

Automated quote collaboration removes roadblocks in your approval workflow

At the same time, pricing data is fully managed by the system, so collaboration between sales reps and sales ops becomes much faster. The sales rep can configure and sell with complete confidence in pricing accuracy, while sale ops simply go through the numbers to ensure accuracy. Approval workflows are automated so that quotes flow seamlessly from sales to other departments and finally the customer.

This approach is increasingly becoming more attractive for manufacturers due to a global labor shortage as it solves challenges on multiple levels. Experienced sales reps become more efficient and can focus on engaging new or more profitable clients. Engineers can focus on innovation and designing new solutions for clients. Sales reps can focus on improving support performance.

Besides streamlining the manufacturing sales process, a fully integrated Digital Sales Platform can even extend this speed and efficiency to customers via an eCommerce portal. When it’s powered by a CPQ, self-serve buying—an feature that more customers are asking for—becomes reality. The CPQ function in a fully digitized sales process enables customers to configure and buy products on their own.

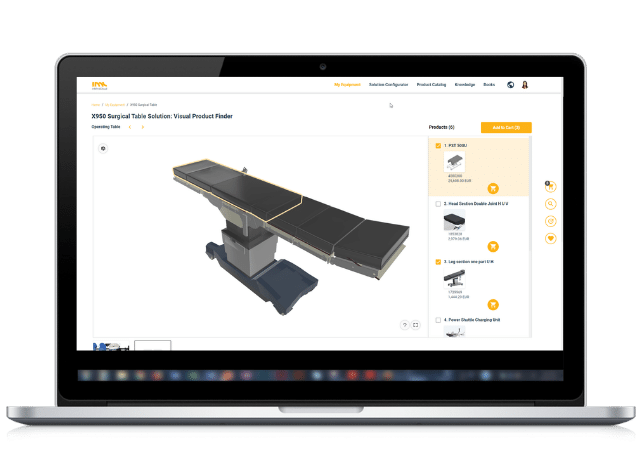

When it’s applied to a manufacturer’s aftersales business, spare parts and consumables are constantly within reach of customers. They can simply log in to the sales portal, find the right products (either by search of automatic recommendations by the system), and either buy directly or start a sales conversation via an inquiry.

Through eCommerce, manufacturers lift the burden of minor inquiries, aftermarket servicing, and requests for information from the sales rep. An online store that’s connected to your ERP, and powered by a CPQ gives customers an effective and efficient way of solving their problems with your solutions.

System guided configuration helps streamline the buying and selling journey

The impact of sales digitization on your manufacturing business’s bottom line

Your manufacturing business is in the pursuit of growth and profitability. That’s not going to change anytime soon. What should change is how your manufacturing business approaches it. Upgrading your facilities and operations is key to growing your business. However, upgrading how your business sells with digital technology is just as important--if not more so.

With digital sales, your business gets a consolidated Digital Sales Platform that manages your entire sales organization and is scalable enough to match your growth. The result is a more streamlined and efficient sales force that is free to focus on bigger, more profitable deals. Manufacturers that have implemented an integrated Digital Sales Platform also enable transparency in sales. This helps their sales teams uncover hidden opportunities in aftersales, or prioritize customer needs to improve revenue generation.

At the same time, customers, partners, dealers, and distributors get unprecedented, 24/7 access to your business and its capabilities—and vice versa. New products and innovations can be instantly in front of them with little to no delay. Opening new markets or sales channels becomes just as simple. Through a single platform your business onboards partners from other geographic locations in minutes. Once they’re fully on board, intelligent guided selling gets them selling immediately.

Features like 3D visualization help customers find the right parts quickly and easily

This is the future of manufacturing sales, and it’s here now. All it needs is a change in perspective. Instead of looking at sales digitization as a cost, manufacturers can think of it as a powerful profit center that pays for itself. To gain a deeper understanding of how digital can transform your sales process, download our Roadmap to Digital Go-to-Market Success ebook. Book a no-obligation demo to discover how your business can leverage In Mind Cloud’s Digital Sales Platform to build your own profit center and see its impact on your bottom line.

Deutsch

Deutsch