Augmented Reality (AR) and Virtual Reality (VR) solutions have been used in consumer-focused productions with great success. But that doesn't mean it's irrelevant for B2B.

If anything, B2B manufacturing companies are pursuing it to improve performance, innovation, and even sales. In a report by PwC research, the use of AR and VR could deliver a US$360 billion GDP boost by 2030. However, one in four manufacturers are not sure how to use it to its full potential.

What is the difference between Augmented Reality and Virtual Reality?

To help you get started, we will first need to get this question out of the way. Augmented reality and virtual reality of very similar technologies--with one major difference between them.

What is Augmented Reality (AR):

3D models or elements are applied on an existing object or landscape. The final image you see is a mix of virtual 3D elements and real world objects or landscapes.

Computer-generated object in a real world environment. Video from Threekit

What is Virtual Reality (VR):

3D models are applied on a completely virtual landscape. The final image you see is made up of 100% computer-generated 3D objects and landscapes.

Computer-generated objects in a computer generated environment. Video from Threekit

While the concept is fairly similar, their usage scenarios can differ greatly. Both AR and VR include screens and cameras, but this does not mean that they are interchangeable when it comes to applications.

AR adds overlays to your physical environment, using filters, sensors, and cameras, while VR obscures your physical environment and then creates a new world digitally.

How are they used in the manufacturing industry?

AR and VR are not new technology, though they are commonly associated with entertainment purposes. Today B2B manufacturing businesses are using it to improve business.

According to The Manufacturer, AR technology is now a powerful tool that the manufacturing industry uses to "achieve remote access, skill retention, and operational productivity."

This outcome is made possible through the use of a concept called "Digital Twin." It is essentially a virtual or digital copy of a factory, a product, or equipment that provides unfettered insight into the inner workings of machinery and systems.

Using AR and VR for manufacturing sales

Manufacturers currently use "Digital Twins" for engineering or training purposes. According to Juniper Research, revenue from this technology will reach $13 billion by 2023. But that's when "Digital Twin" technology is used in conjunction with machine learning, AI, high-performance computing (HPC), and of course, digital sales.

In recent years, many manufacturers are exploring its potential to improve sales by connecting it to sales channels. The idea is to allow customers controlled transparency into a product, machinery, or equipment. The level of detail should be as complete as the customer needs it to be.

For example, in the case of aftersales commerce, information can be segmented by spare parts or consumables. Customers can look at an exploded view of a turbine and immediately see what spare parts it uses (blades, engines, etc.), which ones need replacement, whether or not it's in stock, and how much it costs.

Instead of looking through a large catalog and sifting through thousands of product names and serial numbers, your customers can select their product, and find the right spare part by visually identifying it through your e-commerce portal.

For equipment manufacturers, "Digital Twin" technology can also help your customers understand more clearly how it works and looks.

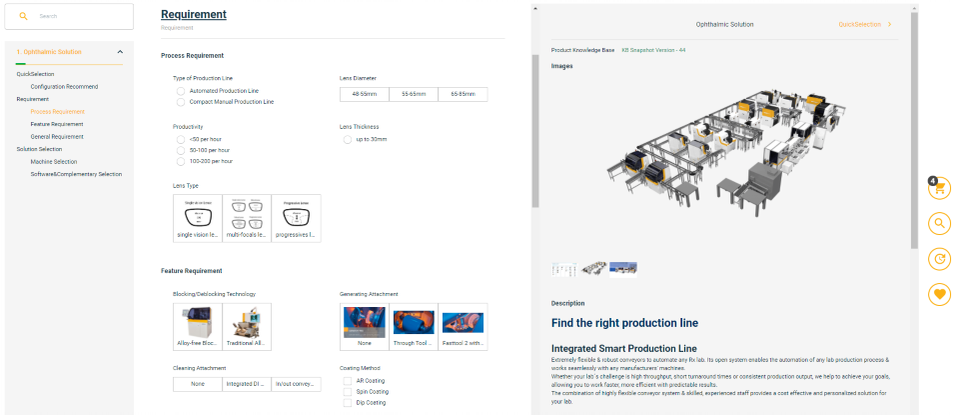

With today's powerful computing power, your customer can easily select the equipment he wants, arrange it on his factory floor, and see how the flow works before even starting a conversation with your sales team.

Helping customers find the right fit (example shows In Mind Cloud Digital Sales Platform)

Helping customers find the right fit (example shows In Mind Cloud Digital Sales Platform)

B2C manufacturers are already using "Digital Twin" technology to great effect. Ikea's IVAR Planner is a great example of how a customer can design a custom shelf, see what it looks like in a room, and buy in one seamless flow.

There is very little reason why manufacturers can't do the same--especially with help from incredibly powerful 3D software like Threekit (an In Mind Cloud partner).

With Threekit, manufacturers can easily create highly accurate 3D models of their products. This is especially useful for manufacturers that offer complicated configuration options for their products. Here's an example of how it can be used.

Configuring a product can become much easier (example shows In Mind Cloud Digital Sales Platform)

3D configuration allows the customer to quickly select, and configure the product according to their needs. Instant calculation of prices allows customers to immediately see if their preferred configuration fits their budget.

Conclusion

"Digital Twin" technology can be used to create a powerful customer experience that is only possible with your deep product knowledge and is not easily replicated by competitors such as B2B marketplaces. It is a huge advantage when it comes to optimizing the customers' buying journey.

When connected to your sales channels, it can provide your customers with a high-quality buying experience, and make it easier for partners and distributors to sell your products. But most important of all, it can make the configuration and buying process much faster than ever before.

The opportunity to sell complex real-world products easily in a virtual environment is here. When paired with a Digital Sales Platform, your manufacturing business has the potential to give your customers the buying experience they expect.

Find out how you can build a digital foundation for your sales channels, and use a built-for-manufacturing e-commerce solution to accelerate manufacturing sales. You can also download a copy of our Manufacturing Commerce Playbook to understand how you can launch your own online sales channel in three months or less.

Deutsch

Deutsch